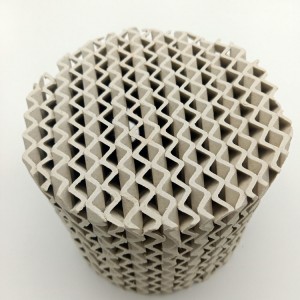

7 Holes High Alumina Honeycomb Ceramic Ring Al2O3 Porous Ceramic Support Catalyst Carrier

7 Holes High Alumina Honeycomb Ceramic Ring Al2O3 Porous Ceramic Support Catalyst Carrier

7 Holes honeycomb alumina catalyst carrier is mainly made of high-purity alumina as raw material, utilizing its high porosity, high porosity, and high gas-liquid separation rate to improve the reaction effect of gas-liquid distribution, thereby enhancing the efficiency of gas-liquid reaction. Compared to traditional products, delivery efficiency can be improved by 300-400%. As a catalyst carrier, it is easy to operate catalysis and is mainly used in the petrochemical industry.

|

Al2O3+SiO2

|

Al2O3

|

Fe2O3

|

MgO

|

K2O+Na2O +CaO

|

Other

|

|

> 99%

|

98-99%

|

<0.06%

|

<0.06%

|

<0.1%

|

<0.1%

|

|

Unit

|

Data

|

Value

|

|

Diameter

|

mm

|

18mm

|

|

Height

|

mm

|

16mm

|

|

Hole size

|

mm

|

3mm

|

|

Unit weight

|

g

|

4.95

|

|

Bulk density

|

g/ml

|

0.45

|

|

Strength

|

N/cm

|

60

|

|

Pore volume

|

ml/g

|

0.76

|

|

Surface Area

|

m2/g

|

222.98

|

|

Water absorption

|

%

|

74

|

|

Maximum Operating Temperature

|

℃

|

1650

|

|

Soften humidity

|

℃

|

1730

|

|

Acid resistance

|

%

|

99.54

|

|

Specific heat

|

KJ/Kg.k

|

1.2~1.4

|

|

Fastness to alkali

|

%

|

98.05

|

*

1. High porosity and good gas-liquid distribution effect.

2. Large specific surface area and low resistance.

3. High acid resistance and good acid resistance.

4. Easy to use and should be widely used.