Best quality Inert Ceramic Ball - Alumina Ceramic Balls as Grinding Media for Mining Minerals – Bestn

Best quality Inert Ceramic Ball - Alumina Ceramic Balls as Grinding Media for Mining Minerals – Bestn

Best quality Inert Ceramic Ball - Alumina Ceramic Balls as Grinding Media for Mining Minerals – Bestn Detail:

1) Grinding ceramic ball is one ideal ball mill grinding media, it can keep the purity and improve the stability of grinded materials.

2) The alumina grinding ball have been widely used in ball mills as abrasive media for ceramic raw materials and glaze materials in ceramic factories, cement factories, enamel factories and glasswork.

3) The main features are high density, high hardness and strength, high wear resistance, thermal stability, corrosion resistance and non-pollution etc.

4) During the abrasive/grinding processes, ceramic balls will not be broken, it will not contaminate the materials to be grinded.

5) Type: According to the content of aluminum oxide: 60-70%, 65-75%, 95%.

|

Specification |

65Alumina Ball |

75Alumina Ball |

90Alumina Ball |

92Alumina Ball |

95Alumina Ball |

99Alumina Ball |

|

Al2O3(%) |

≥65 |

≥75 |

≥90 |

≥92 |

≥95 |

≥99 |

|

Fe2O3(%) |

≤0.5 |

≤0.5 |

≤0.1 |

≤0.1 |

≤0.1 |

≤0.1 |

|

Moh’s Hardness |

8 |

8~9 |

9 |

9 |

9 |

9 |

|

Water Adsorption (%) |

≤0.05 |

≤0.05 |

≤0.02 |

≤0.02 |

≤0.02 |

≤0.01 |

|

Density (g/cm3) |

≥2.95 |

≥3.25 |

≥3.55 |

≥3.60 |

≥3.65 |

≥3.8 |

|

Crush Strength (MPa) |

≥1650 |

≥1700 |

≥1900 |

≥2000 |

≥2250 |

≥2500 |

|

Abrasion Loss (%) |

≤0.03 |

≤0.02 |

≤0.01 |

≤0.01 |

≤0.01 |

≤0.01 |

|

High Alumina Grinding Balls |

Medium Alumina Grinding Balls |

Carbonized Alumina Grinding Balls |

|

|

Color |

White |

White |

Ash-black |

|

Crack |

Not Permission |

Not Permission |

Not Permission |

|

Impurity |

Not Permission |

Not Permission |

Not Permission |

|

Foam hole |

Above ф1mm not permission, size in ф0.5mm permit 3 balls |

||

|

Flaw |

Max. size in ф0.3mm permit 3 balls |

||

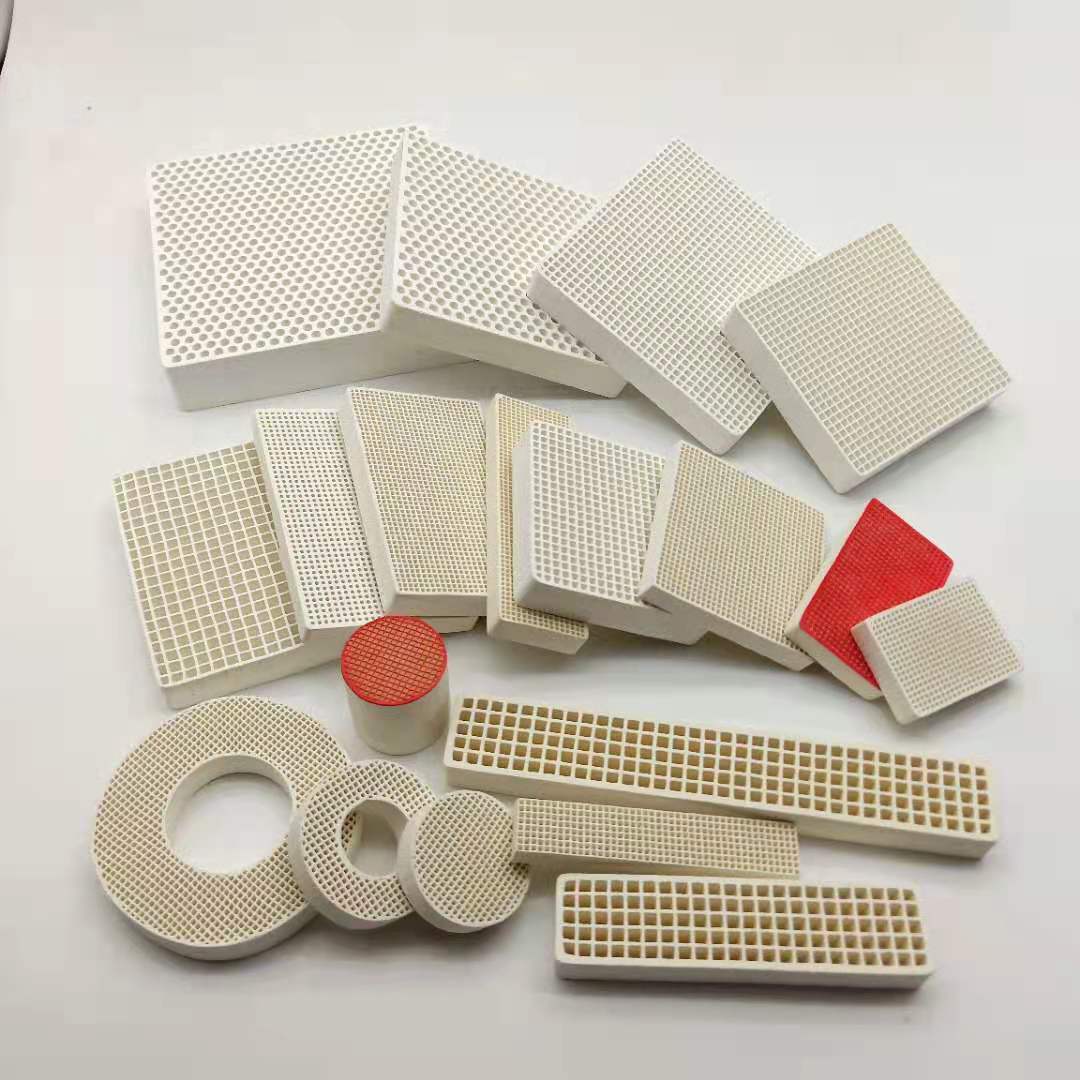

Product detail pictures:

Related Product Guide:

Our merchandise are commonly identified and dependable by end users and will meet continually altering financial and social desires for Best quality Inert Ceramic Ball - Alumina Ceramic Balls as Grinding Media for Mining Minerals – Bestn , The product will supply to all over the world, such as: Korea, Mexico, Angola, We have exported our products all over the world, especially the USA and European countries. Furthermore, all of our products are manufactured with advanced equipment and strict QC procedures to ensure high quality.If you are interested in any of our products, please don't hesitate to contact us. We will try our best to meet your needs.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.