-

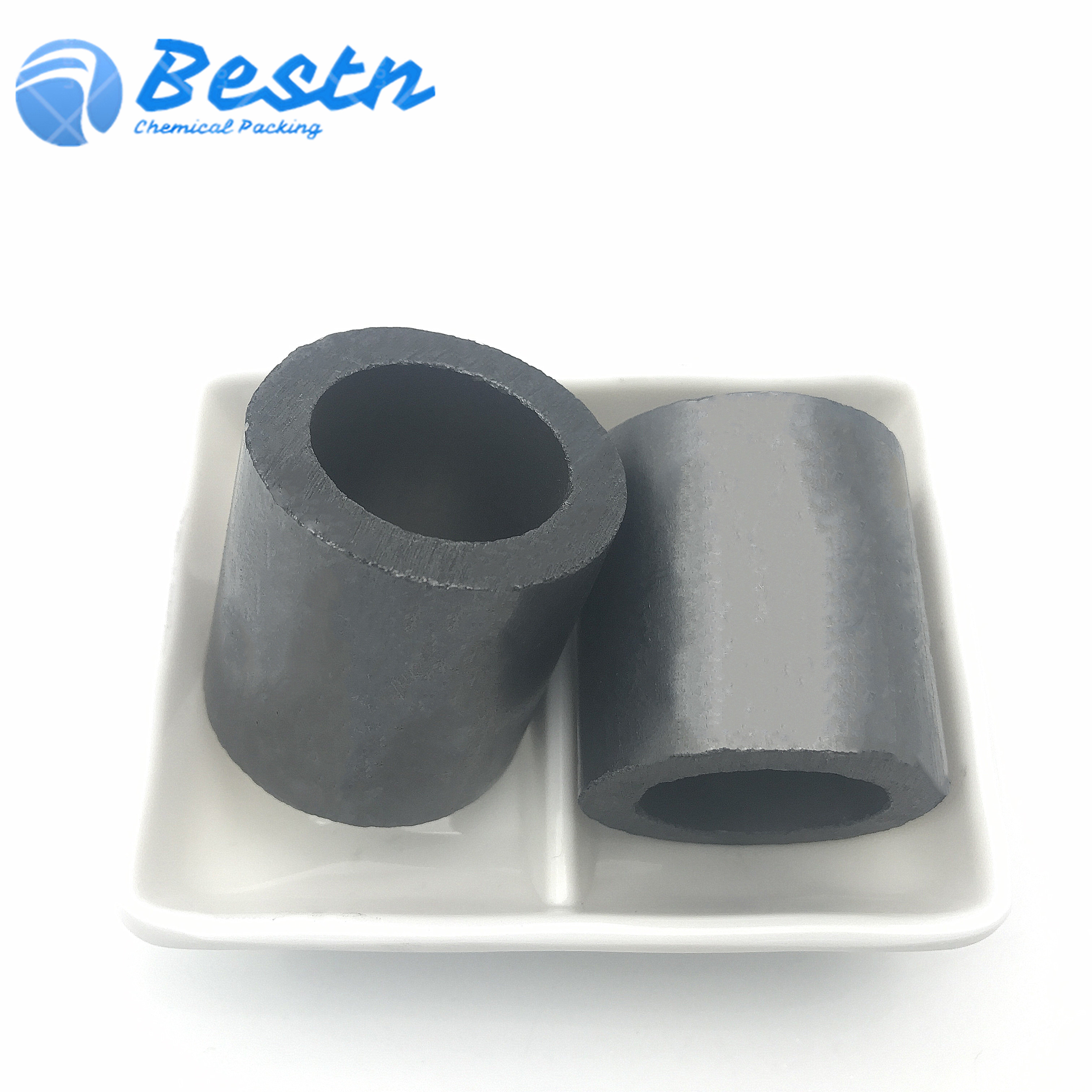

High-Performance Graphite Raschig Rings – Superior Corrosion Resistance & Custom Sizes for Harsh Chemical Processes

Carbon (Graphite) Rasching Ring is featured with strong resistance in HF, strong acid, or strong alkali Environment, where packings made of other material, such as ceramic, plastic, and metal, can easily be corroded.

-

99% Alumina Ceramic Heating Core Hot Air Welding Gun Heating Core

Alumina ceramic parts are a type of ceramic material mainly composed of high-purity alumina (Al ₂ O3), which has extremely high hardness, wear resistance, high temperature resistance, and chemical stability. It is widely used in multiple industrial fields and is currently the largest and most widely used industrial ceramic material in terms of production volume. Item Al₂O₃≥99% Al₂O₃≥95% ZrO₂≥94% Physicalproperties Density 3.85 3.6 5.9 Water Absorption % 0 0 0 Sintering temperature °... -

Customize 99% Alumina Ceramic Crucible with High Temp Resistance in Metal Melting and Lab

Alumina ceramic crucible is a ceramic container made of high-purity aluminum oxide (usually with a content greater than 99%), widely used for high-temperature sintering, melting and chemical analysis. Item Index Value Chemical composition Al2O3 ≥99% R2O3 ≤0.2% Fe2O3 ≤0.1% SiO2 ≤0.2% Bulk density(g/cm3) ≥3.8 Apparent porosity(%) <1 Bending Strength (4pt) >350 Compressive strength(Kgf/cm2) >12000 Dielectric constant(E) ... -

Tower Packing Ceramic Cascade Mini Ring for Chemical Industrial Scrubbers

Ceramic cascade mini ring can be used in the drying columns, absorbing columns, cooling towers, scrubbing towers and actifier columns in chemical industry, metallurgy industry, coal gas industry, oxygen producing industry, etc.

-

Ceramic Filter Media Random Packing Ceramic Lessing Ring for RTO Plants

Ceramic lessing ring is a packing designed basically from the raschig ring with partitions inside to increase the surface and enhance the transfer efficiency.

-

High Alumina Honecycomb Heat Exchanger Ceramic Proppant/Filter Catalyst for Mechanical Equipment

Honeycomb catalyst carrier is mainly use high purity aluminum oxide as raw materials, Use its high porosity gap rate, high rate of segmentation in the gas and liquid to improve the reaction effect of gas and liquid distribution , thus improve the reaction efficiency of gas and liquid. Compared with traditional products, the distribution efficiency can be increased by 300-400 percent.

-

Tower Packing Graphite Carbon Raschig Ring for Petrochemical Industry

Carbon (Graphite) Rasching Ring is featured with strong resistance in HF, strong acid, or strong alkali Environment, where packings made of other material, such as ceramic, plastic, and metal, can easily be corroded.

-

Ceramic Cross-Partition Ring Tow Packing for Drying Cooling Tower

Ceramic cross ring is based on increased surface area of filter to enhance the efficiency of mass transfer on the idea and developed a new ceramic packing, the structure is added in the raschig rings in the cross partition. In general, this packing the large size, only applied to neat pile, the current cross ring is generally used as lumber distribution layer with the bottom support. 80-150mm size of the ceramic can be used for supporting cross ring material, porosity greater than 60%.

-

Ceramic ball arches and high-strength sulfuric acid drying tower ball arches

Ball arches are acid resistant ceramic products made from clay and other ceramic raw materials through molding, sintering, and other processes. They are mainly composed of arch bricks, arch foot bricks, cores, and other components, and are mainly used to support the fillers in industrial towers. The large opening all ceramic spherical arch is a new type of support structure for sulfuric acid drying towers and absorption tower fillers. It is a major transformation of the original granite, cast iron grate plate support structure, etc. According to the specific requirements and needs of sulfuric acid and other chemical equipment, it is designed as an arch structure. Compared with the old structure, it is composed of several large acid resistant tiles, which have good mechanical properties, high safety factor, uniform gas distribution, good stability, strong corrosion resistance, convenient construction, and long service life. The application effect in the sulfuric acid industry is good. Ball arches are mainly divided into two types: single layer and double layer. The main components of ceramic ball arches are as follows: Arch brick: It is the main structural part of a spherical arch and is a ceramic tile in the shape of an I-shaped shape. Therefore, it is also commonly known as “I-shaped brick”.

Arch foot brick: The lower component of a spherical arch, which is a ceramic tile with a triangular or trapezoidal shape at the bottom. Arch core: The intermediate component of a spherical arch, which is a conical structure with a cross shaped shape inside. Product specifications: There are two types of acid resistant ceramic ball arches: single layer and double layer. Common specifications include 1.5 meters, 2.0 meters, 25 meters, 3.0 meters, 3.5 meters, 4.0 meters, 4 meters,. 0 meters, 5.5 meters, 6.0 meters, 6.5 meters, and 7.0 meters, which can be customized according to the actual tower diameter. -

7 Holes High Alumina Honeycomb Ceramic Ring Al2O3 Porous Ceramic Support Catalyst Carrier

7 Holes honeycomb alumina catalyst carrier is mainly made of high-purity alumina as raw material, utilizing its high porosity, high porosity, and high gas-liquid separation rate to improve the reaction effect of gas-liquid distribution.

-

Heat Insulation and Fire Prevention Ceramic Fiber Aluminum Silicate Plug

Aluminum silicate plugging sleeve is sometimes also called asbestos plug and insulation cap for the outlet of the aluminum-copper-zinc smelting furnace.

-

Ceramic Super Intalox Ring for Drying Tower Packing

Intalox saddles can be used in the drying columns, absorbing columns, cooling towers, scrubbing towers and actifier columns in chemical industry, metallurgy industry, coal gas industry, oxygen producing industry, etc.