-

25mm 50mm 38mm 76mm Heat Resistance Ceramic Pall Ring Tower Packing

Ceramic pall ring is a type of classical random packing, which is developed from the Raschig ring. Commonly, there are two layers of windows opened along its cylinder wall. Each layer has five ligules bending inward the axes of the ring, which is similar to the metallic pall ring and plastic. But the layer and quantity of ligules may different according to the height and diameter variation.

Generally, the opening area occupies 30% of the total area of the cylinder wall. This design helps vapor and liquid flow freely through these windows, making full use of the inner surface of the ring to improve the distribution of vapor and liquid. It can also improve the separating efficiency.

Ceramic pall ring has excellent acid resistance and heat resistance. It can resist to corrosion of various inorganic acids,organic acids and organic solvents except hydrofluoric acid, and can be used in high or low temperature conditions.

Consequently the application range is very wide. It can be used in the drying columns, absorbing columns, cooling towers,scrubbing towers and actifier columns in chemical industry, metallurgy industry, coal gas industry, oxygen producing industry,etc. -

Tower Packing Rasching Ring Ceramic for Cooling Towers in Chemical Industry

Ceramic raschig ring is the first development of random packing. Its simple shape, its height and diameter are equal. Raschig rings large size (100mm or more) means the general rules by filling the entire puzzle, 90mm size raschig rings generally use the following method loading number.

-

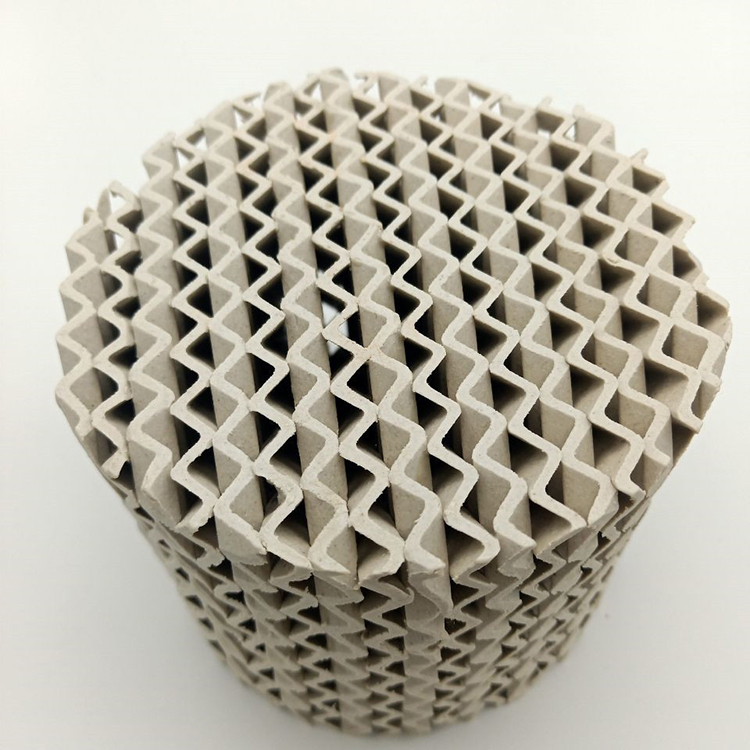

Heat Resistance Ceramic Structured Packing for Tower Packing

Ceramic Structured Packing consists of many packing units of similar geometric design. Corrugated sheets placed in parallel form cylindrical units called corrugated tower packing. These are a form of highly efficient packing with separating efficiency several times higher than that of loose packing. They have the quality of low-pressure drop, increased operating elasticity, minimum amplifying effect, and maximum liquid treatment compared to loose tower packing.