China Wholesale Silicon Carbide/ Alumina /Zirconia Ceramic Porous Foam Honeycomb Filter for Molten Metal Filtration and Low Pressure Casting

China Wholesale Silicon Carbide/ Alumina /Zirconia Ceramic Porous Foam Honeycomb Filter for Molten Metal Filtration and Low Pressure Casting

Well-run equipment, professional sales team, and better after-sales services; We are also a unified big family, everyone stick to the company value “unification, dedication, tolerance” for China Wholesale Silicon Carbide/ Alumina /Zirconia Ceramic Porous Foam Honeycomb Filter for Molten Metal Filtration and Low Pressure Casting, You may obtain the lowest price tag here. Also you may get high quality products and exceptional provider here! Please do not hesitate to call us!

Well-run equipment, professional sales team, and better after-sales services; We are also a unified big family, everyone stick to the company value “unification, dedication, tolerance” for China Alumina Ceramic Foam Filter and Silicon Carbide Ceramic Foam Filter, We hope we can establish long-term cooperation with all of the customers, and hope we can improve competitiveness and achieve the win-win situation together with the customers. We sincerely welcome the customers from all over the world to contact us for anything you need to have!Welcome all customers both at home and abroad to visit our factory. We hope to have win-win business relationships with you, and create a better tomorrow.

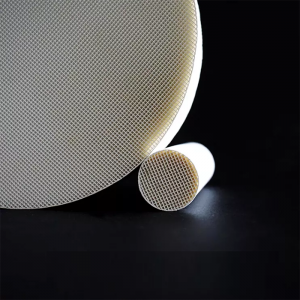

Zirconia Ceramic Foam Filter is a phosphate-free, high melting point, It is characterized by high porosity and mechanochemical stability and excellent resistance to thermal shock and corrosion from molten steel, It can effectively remove inclusions, reduce trapped gas and provide laminar flow when molten zirconia foam filtrated, it is machined to tight dimensional tolerance during production, this combination of physical properties and precise tolerance make them first choice for molten steel,alloy steel, and stainless steel, etc.

|

Dimensions (mm) |

Zirconia Foam Filter |

|

|

Pouring Rate(kg) |

Filtration Capacity(kg) |

|

|

50×50×22 |

3~5 |

30 |

|

50×75×22 |

4~6 |

40 |

|

75×75×22 |

7~12 |

60 |

|

75×100×22 |

8~15 |

80 |

|

100×100×22 |

14~20 |

100 |

|

Dia 50×22 |

2~6 |

18 |

|

Dia 80×22 |

6~10 |

50 |

|

Dia 90×22 |

8~16 |

70 |

1.Filter out the inclusions in the casting, reduce the gas in the casting, reduce the degree of turbulence during

the flow filling of the metal, reduce the surface defects in the casting, and significantly reduce the rejection rate of the casting.

2.Improve the fluidity of molten metal, increase the filling ability and shrinkage ability of the casting, improve

the surface finish of the casting, increase the compression seal of the casting, enhance the elongation and tensile strength, and improve the surface quality and mechanical properties of the casting.

3.It has very high temperature working strength, chemical stability, thermal shock resistance and resistance to metal liquid flow impact. High chemical stability makes it not affected by the acidity and alkalinity of the molten metal and does not change the chemical composition of the molten metal. There is no slag dropping or cracking in the work, which ensures the filtration quality of molten metal and the stability of chemical composition.

4.It has a large metal flow rate, and the flow rate is stable (different from the straight hole ceramic filter, the flow rate gradually decreases with the increase in the number of captured impurities). Its filtering effect is

much higher than that of other filter elements.

5.It has very high dimensional accuracy and can be used in the production line for automatic filter placement.

| Material | Zirconia |

| Color | Yello |

| Pore Density | 10-30ppi |

| Porosity | 80-90% |

| Refractoriness | ≤1700ºC |

| Bending Strength | >0.8Mpa |

| Compression Strength | 1.5Mpa |

| Volume-weight | 0.7-1.0 g/cm3 |

| Thermal shock resistance | 6times/1100ºC |

| Application | Steel casting & cast iron castings |

1.Efficiently filter metal particles impurities such as slag and refractory fragments to the micron level to reduce the loss of tools during machining of castings

2.The molten metal filling is stable and the structure of the casting is uniform, thereby improving the mechanical properties such as surface hardness, tensile strength and fatigue resistance of the casting

3.The three-dimensional mesh structure has a good rectification effect on metal turbulence, and has a good control effect on non-metallic inclusions and secondary oxidation caused by turbulent erosion of the cavity.

4.Simplified gating system and improved cavity utilization

5.The surface of the casting is clean, reducing the machining allowance, shortening the cleaning time, and improving the delivery efficiencyWell-run equipment, professional sales team, and better after-sales services; We are also a unified big family, everyone stick to the company value “unification, dedication, tolerance” for China Wholesale Silicon Carbide/ Alumina /Zirconia Ceramic Porous Foam Honeycomb Filter for Molten Metal Filtration and Low Pressure Casting, You may obtain the lowest price tag here. Also you may get high quality products and exceptional provider here! Please do not hesitate to call us!

China Wholesale China Alumina Ceramic Foam Filter and Silicon Carbide Ceramic Foam Filter, We hope we can establish long-term cooperation with all of the customers, and hope we can improve competitiveness and achieve the win-win situation together with the customers. We sincerely welcome the customers from all over the world to contact us for anything you need to have!Welcome all customers both at home and abroad to visit our factory. We hope to have win-win business relationships with you, and create a better tomorrow.