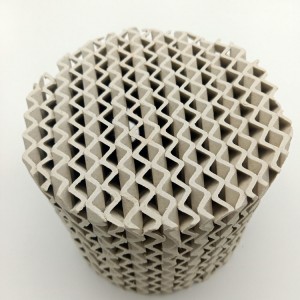

Customize 99% Alumina Ceramic Heating Core Hot Air Welding Gun Heating Core

Customize 99% Alumina Ceramic Heating Core Hot Air Welding Gun Heating Core

Alumina ceramic parts are a type of ceramic material mainly composed of high-purity alumina (Al ₂ O3), which has extremely high hardness, wear resistance, high temperature resistance, and chemical stability. It is widely used in multiple industrial fields and is currently the largest and most widely used industrial ceramic material in terms of production volume.

|

Item

|

Al₂O₃≥99%

|

Al₂O₃≥95%

|

ZrO₂≥94%

|

|

|

Physical

properties

|

Density

|

3.85

|

3.6

|

5.9

|

|

Water Absorption %

|

0

|

0

|

0

|

|

|

Sintering temperature °C

|

1690

|

1670

|

1650

|

|

|

Quality characteristics

|

Hardness HV

|

1700

|

1600

|

1400

|

|

Flexural strength 4pt

|

>3500

|

>2900

|

>11000

|

|

|

Compressive strength /cm²

|

30000

|

25000

|

25000

|

|

|

Thermodynamicproperties

|

Maximum service temperature °C

|

1500

|

1400

|

1600

|

|

Coefficient of thermal expansion

|

8

|

7.8

|

10

|

|

|

10-6/°C

|

||||

|

0-1000°C

|

||||

|

Heat shock resistance (°C)

|

200

|

220

|

350

|

|

|

Thermal conductivity W/m.k

|

31

|

22

|

3

|

|

|

Electrical

characteristics

|

Volume resistivity Ω.cm

|

>10^12

|

>10^12

|

>10^12

|

|

Breaking strength of insulation KT/m

|

18

|

16

|

15

|

|

|

Dielectric constant 1MHZ(E)

|

9.2-10.5

|

9.0-10

|

12.5

|

|

|

Length(mm)

|

Width(mm)

|

Height(mm)

|

Wall thickness(mm)

|

Capacity(cc)

|

|

6-200

|

30-150

|

15-190

|

>2

|

5-5000

|

1. High hardness and wear resistance Hardness:

The Mohs hardness of alumina ceramics is as high as level 9, second only to diamond. Wear resistance: Its wear resistance is 266 times that of manganese steel and 171.5 times that of high chromium cast iron.

2. High temperature resistance and thermal stability

High temperature resistance: The melting point of alumina ceramics is as high as 2050 ℃, and it can maintain stable performance at a high temperature of 2000 ℃. Thermal stability: It has a low coefficient of thermal expansion and can maintain structural stability under extreme temperature changes.

3. Lightweight design Density:

The density of alumina ceramics is only 3.6-3.8g/cm ³, which is over 50% lighter than steel. For example, using alumina ceramic components in airplanes can reduce weight by 30% and significantly improve fuel efficiency.

4. Corrosion resistance and insulation properties Corrosion resistance:

Excellent resistance to strong acids, alkalis, and salt media, suitable for chemical reactors, anti-corrosion valves, etc. Insulation: With a resistivity of ≥ 1 × 10 ¹⁴Ω· cm, it is the preferred material for high-frequency electronic device substrates.

5. High cost-effectiveness Cost effectiveness:

Its long lifespan and low maintenance characteristics significantly dilute long-term costs.

- Mechanical and structural ceramics: used for bearings, sliders, seals, etc., to reduce failures and downtime.

- Chemical and high-temperature industries: used as refractory materials, insulation materials, chemical reactor liners, and pipeline fittings.

- Electronics/Power: Used for electronic substrates, insulation sleeves, etc., providing high insulation performance.

- Medical: Used for artificial joints, dental implants, etc., with excellent biocompatibility.

- Aerospace: Used for engine components, turbine blades, etc., to enhance the reliability of power systems