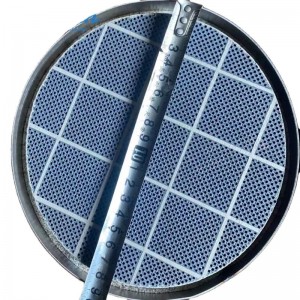

Customize Euro 1-6 Metal DPF Motorcycle Catalytic Converter BMW Metal Carrier

Customize Euro 1-6 Metal DPF Motorcycle Catalytic Converter BMW Metal Carrier

|

Shape

|

Shell size(mm)

|

Core size(mm)

|

Cell density(CPSI)

|

|

Rotundity

|

Φ 30×22

|

Φ 28×20

|

100/200/300/400

|

|

Rotundity

|

Φ 35×20

|

Φ 33×20

|

100/200/300/400

|

|

Rotundity

|

Φ 35×30

|

Φ 33×30

|

100/200/300/400

|

|

Rotundity

|

Φ 35×40

|

Φ 33×40

|

100/200/300/400

|

|

Rotundity

|

Φ 35×50

|

Φ 33×50

|

100/200/300/400

|

|

Rotundity

|

Φ 35×60

|

Φ 33×60

|

100/200/300/400

|

|

Rotundity

|

Φ35 × 70/100/130

|

Φ33 × 60/90/120

|

100/200/300/400

|

|

Rotundity

|

Φ42 × 70/100/130

|

Φ40 × 60/90/120

|

100/200/300/400

|

|

Rotundity

|

Φ45 × 70/100/130

|

Φ43 × 60/90/120

|

100/200/300/400

|

|

Rotundity

|

Φ63,5 × 85/100/130

|

Φ60,5 × 74,5/90/120

|

200/300/400

|

|

Rotundity

|

Φ73 × 70/100/130 L

|

Φ70 × 60/90/120

|

200/300/400

|

|

Rotundity

|

Φ93 × 70/100/130

|

Φ90 × 60/90/120

|

200/300/400

|

|

Rotundity

|

Φ100,3 × 100/130

|

Φ98,3 × 90/120

|

600

|

|

Rotundity

|

Φ144 × 150/152,4

|

Φ142 × 140/142,4

|

200/300/400

|

|

Rotundity

|

Φ190 × 200

|

Φ188 × 190

|

200/300/400

|

|

Rotundity

|

Φ420 × 100/130

|

Φ416 × 90/120

|

300/400

|

|

Race track

|

123×63×85

|

120×60×75

|

200/300

|

|

Race track

|

123×63×100

|

120×60×90

|

200/300

|

|

Race track

|

78,5×52×104

|

76,5×50×90

|

200/300

|

|

Emission standard

|

Euro2, Euro3, Euro4, Euro5, Euro6; EPA and CARB

|

||

|

Engine compliance

|

petrol engines, diesel engines and generators

|

||

|

Active catalyst ingredients

|

Pt, Pd, Rh, and rare earth elements

|

||

|

Substrates material

|

metallic (FeCrAL)

|

||

Shape: Round, oval, racetrack, rectangle and other especial shape according to the design of client.

Type: Spirality series, "S" series and "SM" series.

Type: Spirality series, "S" series and "SM" series.

Please note: 1. Please do not use leaded gasoline. 2. Please do not run rapidly for a long time (open loop control state). 3. Please don't let the engine speed go up and down. 4. Please do not fire too late. 5. It can't be started for a long time. 6. Do not pull out the high-voltage line for a long time to test the fire.

Coating:Can be Coated with Pt, Pd, Rh base on different demands to meet Euro 2-5, EPA, CARB standard.

Compared to ceramic substrate, metal substrate has more advantages:

1. Better heat conduction, fast heating.

2. Lower back pressure.

3. Larger effective area.

4. Greater catalytic capacity.

5. Smaller and more flexible design.

6. Thinner wall.

7. Higher mechanical strength.

8. Better resistance to thermal shock and resistance to thermal fatigue.

9. Longer service life.

1. Round & Oval metallic substrate for On-road vehicle.

2. Metallic substrate for small engine.

3. Metallic substrate for Off-road vehicle.

4. Metallic substrate for industrial catalyst.

5. Specific structure metallic substrate for other application.