Facroty Price Ceramic Saddles Tower Packing – Ceramic Filter Media Random Packing Ceramic Lessing Ring for RTO Plants – Bestn

Facroty Price Ceramic Saddles Tower Packing – Ceramic Filter Media Random Packing Ceramic Lessing Ring for RTO Plants – Bestn

Facroty Price Ceramic Saddles Tower Packing – Ceramic Filter Media Random Packing Ceramic Lessing Ring for RTO Plants – Bestn Detail:

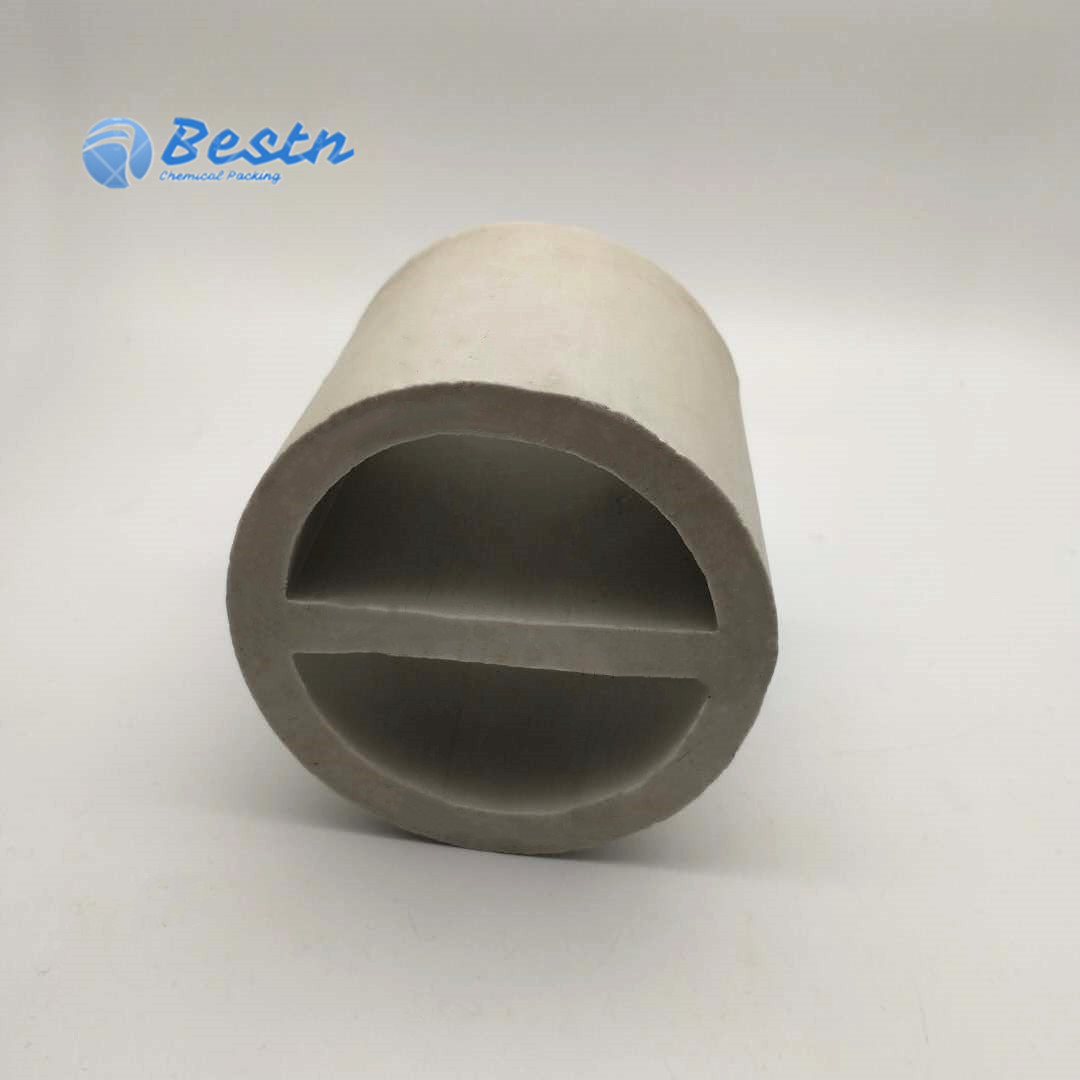

Ceramic lessing ring is a packing designed basically from the raschig ring with partitions inside to increase the surface and enhance the transfer efficiency. It is usually used extensively for the supporting packing at the bottom of tower. It has high density and excellent acid resistance and it withstands the corrosion of various inorganic acid, organic acid and organic solvents expect for hydrofluoric acid.

| Technical Data: | |||

| SiO2 + Al2O3 | >92% | CaO | <1.0% |

| SiO2 | >70% | MgO | <0.5% |

| Al2O3 | >17-23% | K2O+Na2O | <3.5% |

| Fe2O3 | <1.0% | Other | <1% |

| Physical & Chemical Properties: | |||

| Water absorption | <0.5% | Moh’s hardness | >6.5 scale |

| Porosity | <1% | Acid resistance | >99.6% |

| Specific gravity | 2.3-2.40 g/cm3 | Alkali resistance | >85% |

| Dimension and Other Physical Properties: | |||||

| Size |

OD*ID*H*T (mm) |

Weight per M3(kg/m3) | Number per M3 (Pcs/m3) | Surface Area (m2/m3) | Dry packing factor m-1 |

| 10mm | 10*6*8*2 | 800 | 750000 | 420 | 1250 |

| 2 ”(50mm) | 50*40*50*5 | 600 | 6500 | 145 | 565 |

| 3” (80mm) | 80*64*80*8 | 820 | 1950 | 120 | 356 |

| 4” (100mm) | 100*80*100*10 | 850 | 1000 | 110 | 252 |

| 5” (120mm) | 120*96*120*12 | 860 | 370 | 75 | 146 |

| 6” (150mm) | 150*120*150*15 | 980 | 296 | 60 | 101 |

The ceramic lessing ring has high density and excellent acid and heat resistance, and can resist corrosion of various inorganic acids, organic acids and organic solvents except hydrofluoric acid. Ceramic inline ring is a kind of ceramic random packing, which has the advantages of large flux, pressure drop and high efficiency.

The ceramic lessing ring can be used in drying towers, absorption towers, cooling towers, washing towers, regeneration towers, etc. in chemical, metallurgy, gas, environmental protection and other industries.

Product detail pictures:

Related Product Guide:

Our merchandise are commonly recognized and reliable by customers and can meet constantly developing economic and social desires for Facroty Price Ceramic Saddles Tower Packing – Ceramic Filter Media Random Packing Ceramic Lessing Ring for RTO Plants – Bestn , The product will supply to all over the world, such as: Hanover, Armenia, Comoros, We are your reliable partner in the international markets of our products. We focus on providing service for our clients as a key element in strengthening our long-term relationships. The continual availability of high grade products in combination with our excellent pre- and after-sales service ensures strong competitiveness in an increasingly globalized market. We are willing to cooperate with business friends from at home and abroad, to create a great future. Welcome to Visit our factory. Looking forward to have win-win cooperation with you.

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.