Facroty Price Ceramic Saddles Tower Packing – Ceramic Super Intalox Ring for Drying Tower Packing – Bestn

Facroty Price Ceramic Saddles Tower Packing – Ceramic Super Intalox Ring for Drying Tower Packing – Bestn

Facroty Price Ceramic Saddles Tower Packing – Ceramic Super Intalox Ring for Drying Tower Packing – Bestn Detail:

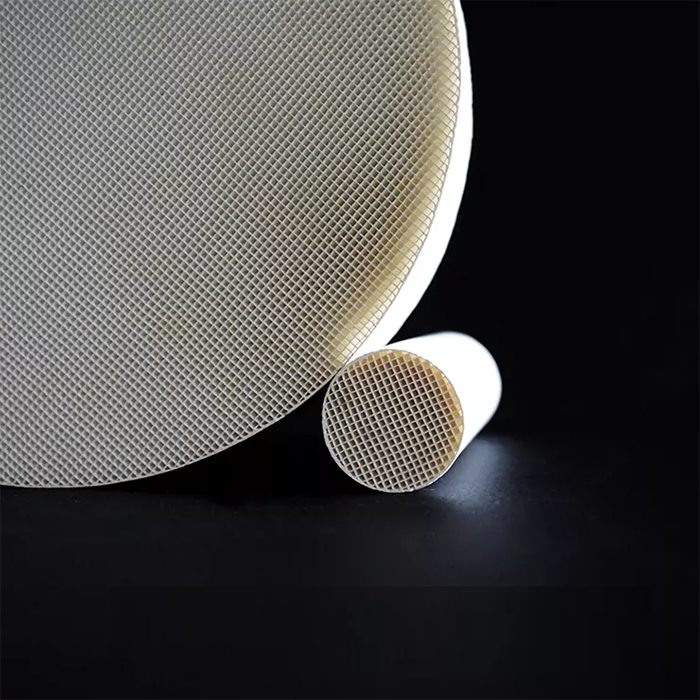

Ceramic Super Saddle Ring Packing improves on the new packing from the saddle moment, filling the smooth saddle moment to the raised fringe of the zigzag or curved sides. This layer is in the packed bed, which increases the contact gap between the packings, so that there is more gas-liquid flow and dispersion in the packing layer. It has the characteristics of pressure reduction and high mass transfer efficiency, and is widely used in the production of sulfuric acid. Drying towers and absorbers. At the same time, it has excellent acid resistance and heat resistance, and can resist the corrosion of various inorganic acids, organic acids and organic solvents except hydrofluoric acid, and can be used under high or low temperature conditions. Therefore,the application range is very wide.

| Chemical Analysis | |

| Composition | Value |

| SiO2 | >69% |

| Al2O3 | 17-23% |

| SiO2+ Al2O3 | >92% |

| Fe2O3 | <1.0% |

| CaO | <0.25% |

| MgO | <2% |

| K2O+Na2O | 2-4% |

| Other | <1% |

| Physical properties | ||

| Index | Unit | Value |

| Porosity | Vol% | 1 |

| Specific heat | KJ/Kg | 840-900 |

| Crush strength | N/mm2 | 390-420 |

| Specific gravity | g/cm3 | 2.3-2.45 |

| Acid Resistance | % | 99.98 |

| Firing temperature | °C | 1280 to 1320 |

| Softening point | °C | >1400 |

| Water absorption | % | <0.2 |

| Thermal Expansion | 10-6mm/mm°C | 4.7 |

| Hardness | Mohr Scale | ’7-8 |

| Comprehensive strength | Newtons | 5600 |

| Shock strength | Kgf.cm/cm2 | 1.0-1.5 |

| Geometric properties | ||||||

| Normal Size | Approx. Weight | Surface area | Void Fraction(%) | Dry Packing factor(m-1) | ||

| 1b/ft3 | Kg/m3 | ft2/ft3 | m2/m3 | |||

| 1″ | 40 | 645 | 79.5 | 260 | 77 | 570 |

| 1.5″ | 37.5 | 600 | 64 | 210 | 78 | 430 |

| 2″ | 35.6 | 570 | 42.8 | 140 | 79 | 277 |

| 3″ | 36 | 580 | 32 | 105 | 77 | 206 |

1.These super saddles are made from chemical porcelain and have excellent resistance to acids except in the case of hydrofluoric

acid.Moisture absorption must less than half a percent.

2.The porcelain’s specific gravity is 2.3-2.4g/cm3 and an average heat capacity (between 20ºC and 500ºC of 0.22 cal/g.ºC)

3.Ceramic super intalox saddles softening point is 1400ºC min. And they show good thermal shock resistance during repeated cycling

between 20ºC and 820 ºC.

The packing can be used in the drying columns, absorbing columns, cooling towers, scrubbing towers and actifier columns in chemical industry, metallurgy industry, coal gas industry, oxygen producing industry, etc.

Product detail pictures:

Related Product Guide:

We believe in: Innovation is our soul and spirit. High-quality is our life. Purchaser need is our God for Facroty Price Ceramic Saddles Tower Packing – Ceramic Super Intalox Ring for Drying Tower Packing – Bestn , The product will supply to all over the world, such as: Brazil, panama, Tunisia, Please really feel free to send us your requirements and we'll respond to you asap. We have got a professional engineering group to serve for your just about every detailed needs. Cost-free samples could be sent for you personally to understand much more information. In an effort to meet your requires, please really feel free to make contact with us. You may send us emails and contact us directly. Moreover, we welcome visits to our factory from around the globe for much better recognizing of our organization. nd items. In our trade with merchants of numerous countries, we usually adhere for the principle of equality and mutual benefit. It is actually our hope to market, by joint efforts, each trade and friendship to our mutual advantage. We look forward to getting your inquiries.

In China, we have purchased many times, this time is the most successful and most satisfactory, a sincere and realiable Chinese manufacturer!