Facroty Price Ceramic Saddles Tower Packing – Tower Packing Graphite Carbon Raschig Ring for Petrochemical Industry – Bestn

Facroty Price Ceramic Saddles Tower Packing – Tower Packing Graphite Carbon Raschig Ring for Petrochemical Industry – Bestn

Facroty Price Ceramic Saddles Tower Packing – Tower Packing Graphite Carbon Raschig Ring for Petrochemical Industry – Bestn Detail:

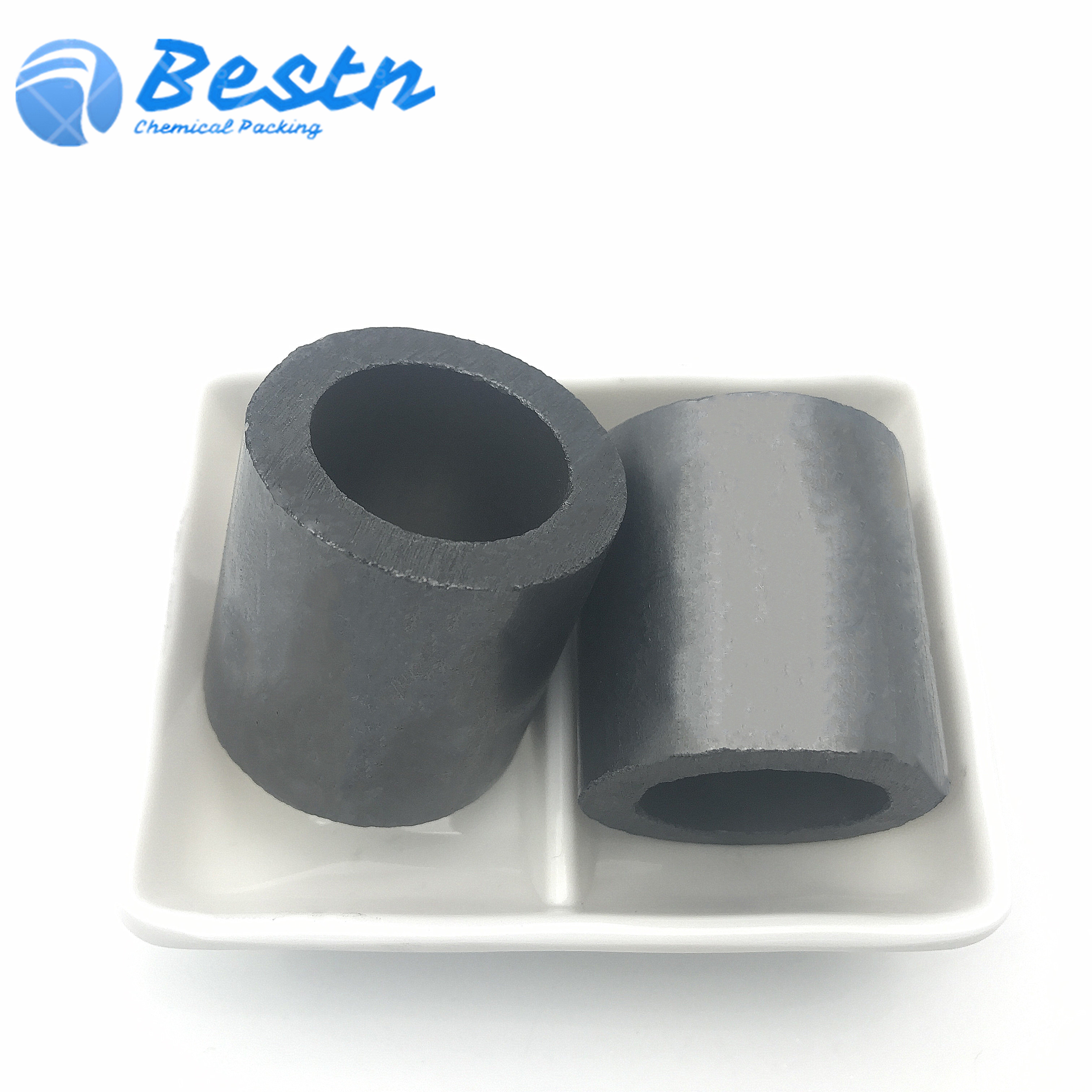

Graphite Raschig ring is a kind of graphite material ring, with the same circle and diameter, chemical packing which is resistant to hydrogen, acid, strong acid and alkali. The temperature can be as high as 200 ºC, and the temperature can reach 48% of the corrosion resistance with sulfuric acid, potassium hydroxide, organic acid salts, most solvents and alkaline substances such as sodium hydroxide, etc.

| Specification | D*H*T | Surface area | Void Space | Bulk Density | Bulk Numbers | Packing factor |

| mm | m2/m3 | m3/m3 | kg/m3 | pcs/m3 | m-1 | |

| BSGRR-13 | 13*13*2 | 329 | 0.684 | 600-650 | 320000 | 1028 |

| BSGRR-19 | 19*19*3 | 220 | 0.54 | 600-650 | 110500 | 914 |

| BSGRR-25 | 25*25*4 | 194 | 0.73 | 600-650 | 46150 | 565 |

| BSGRR-38 | 38*38*6 | 125 | 0.68 | 600-650 | 14000 | 406 |

| BSGRR-50 | 50*50*7 | 120 | 0.78 | 500-550 | 6000 | 252 |

| BSGRR-80 | 80*80*9 | 76 | 0.68 | 650-700 | 1400 | 243 |

| The above figures are for raschig rings of general specifications only. | ||||||

| Customization as per customers’ size requirements is also available. | ||||||

| Physical performance index | |||

| Item | Value | ||

| Bulk Density, Kg/m3 | ≥1500 | ||

| Compressive strength, Mpa | ≥79.5 | ||

| Bending strength, Mpa | ≥35 | ||

| Thermal conductivity, W/m.k | 31.4-40.7 | ||

| Linear expansion coefficient,1/ºC | 24.7*10-16 (129ºC) | ||

| Heat-resistant temperature, ºC | 400 | ||

The graphite Raschig ring has the characteristics of low pressure drop, large flux, uniform liquid distribution, high mass transfer efficiency, and can absorb various exhaust gases or be used for gas washing and separation. It replaces a large number of ferrous metals and a variety of non-ferrous metals, and is a non-metallic material with excellent corrosion resistance.

Graphite Raschig ring packing is mainly used in practical applications such as gas absorption, acid gas desorption, scrubbing tower, regeneration tower, fertilizer production, etc. It can also be used as a packing in propane stripper and acid gas absorber. It is used in the furnaces and towers of petrochemical equipment such as alkylation and reforming, and in the purification, absorption, condensation, distillation, evaporation, filtration and washing of highly corrosive materials.

Product detail pictures:

Related Product Guide:

Attaining consumer satisfaction is our firm's purpose for good. We'll make wonderful efforts to produce new and top-quality merchandise, meet up with your special necessities and supply you with pre-sale, on-sale and after-sale products and services for Facroty Price Ceramic Saddles Tower Packing – Tower Packing Graphite Carbon Raschig Ring for Petrochemical Industry – Bestn , The product will supply to all over the world, such as: Panama, Kenya, kazan, Now, we are trying to enter new markets where we do not have a presence and developing the markets we have now the already penetrated. On account of superior quality and competitive price , we'll be the market leader, be sure to don??¥t hesitate to contact us by phone or email, if you are interested in any of our solutions.

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!