Facroty Price Ceramic Saddles Tower Packing – Tower Packing Rasching Ring Ceramic for Cooling Towers in Chemical Industry – Bestn

Facroty Price Ceramic Saddles Tower Packing – Tower Packing Rasching Ring Ceramic for Cooling Towers in Chemical Industry – Bestn

Facroty Price Ceramic Saddles Tower Packing – Tower Packing Rasching Ring Ceramic for Cooling Towers in Chemical Industry – Bestn Detail:

Raschig ring is the earliest developed random packing,it’s small tube cutting, which outside diameter is equal to its height, providing a surface for (re)evaporation of the most volatile part in the refluxing distillate.With the characters of high mechanical strength, high chemical stability, and excellent heat endurance, Ceramic Raschig Ring can resist high temperature, acid (except HF), alkali, salt and various organic solvents. It’s widely applied in various packing towers of desiccation, absorption, cooling, washing, and regeneration in industries of petrochemical, chemical, metallurgy, gas and oxygen generation. For raschig ring with big size over 100mm, it’s usually filled in the column orderly. If its size is less than 90mm, raschig ring is stacked in the column randomly.

Dimension and Other Physical Properties

| Sizes | Thickness | Surface area | Free volume | Number | Bulk density | Packing factor |

| (mm) | (mm) | (m2/m3) | (%) | per m3 | (kg/m3) | ( m-1) |

| 6 × 6 | 1.6 | 712 | 62 | 3022935 | 1050 | 5249 |

| 12.5 ×12.5 | 2.4 | 367 | 64 | 377867 | 881 | 1903 |

| 16×16 | 2 | 305 | 73 | 192 500 | 730 | 900 |

| 19×19 | 2.4 | 243 | 72 | 109122 | 801 | 837 |

| 25×25 | 3.2 | 190 | 74 | 47675 | 673 | 508 |

| 38×38 | 4.8 | 121 | 73 | 13667 | 689 | 312 |

| 40×40 | 4.5 | 126 | 75 | 127000 | 577 | 350 |

| 50×50 | 4.5 | 93 | 81 | 6000 | 457 | 220 |

| 50×50 | 6.4 | 92 | 74 | 5792 | 657 | 213 |

| 80×80 | 9.5 | 46 | 80 | 1910 | 714 | 280 |

Chemical Analysis

| Al2O3 | SiO2 | Fe2O3 | CaO | MgO | K2O + Na2O | Other |

| 17-23% | >70% | <1.0% | <1.% | <0.5% | <3.5% | <1% |

The packing can be used in the drying columns, absorbing columns, cooling towers, scrubbing towers and actifier columns in chemical industry, metallurgy industry, coal gas industry, oxygen producing industry, etc.

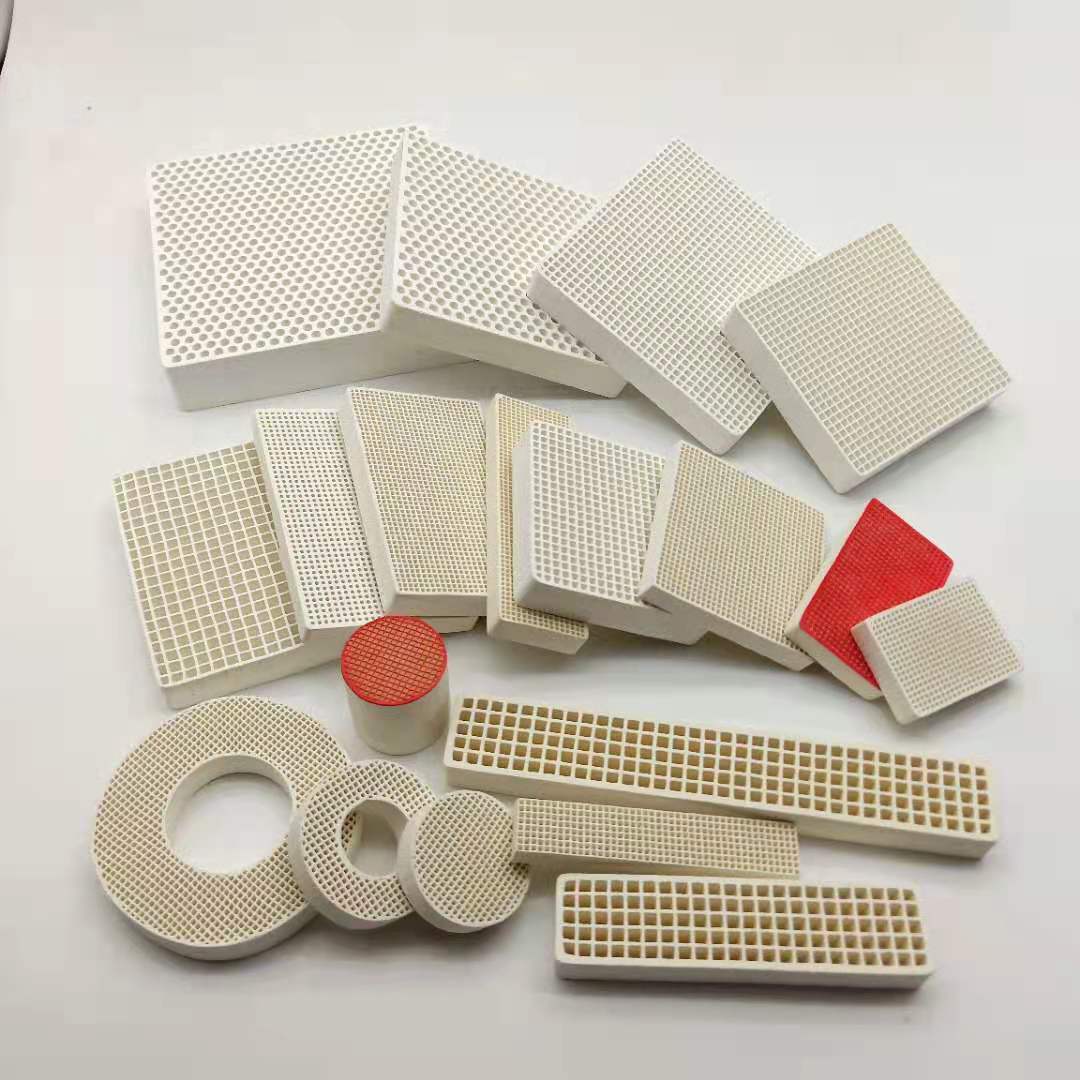

Product detail pictures:

Related Product Guide:

We constantly carry out our spirit of ''Innovation bringing advancement, Highly-quality guaranteeing subsistence, Administration selling advantage, Credit rating attracting buyers for Facroty Price Ceramic Saddles Tower Packing – Tower Packing Rasching Ring Ceramic for Cooling Towers in Chemical Industry – Bestn , The product will supply to all over the world, such as: Wellington, Holland, Portland, Our products are widely sold to Europe, USA, Russia, UK, France, Australia, Middle East, South America, Africa, and Southeast Asia, etc. Our products are highly recognized by our customers from all around the world. And our company is committed to continually improving effectiveness of our management system to maximize customer satisfaction. We sincerely hope to make progress with our customers and create a win-win future together. Welcome to join us for business!

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.