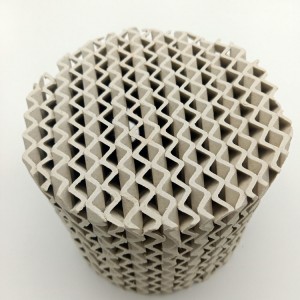

High quality Customized Inert Alumina Ceramic Packing Catalyst Support Media Porcelain Ball

High quality Customized Inert Alumina Ceramic Packing Catalyst Support Media Porcelain Ball

We continue to keep increasing and perfecting our solutions and service. At the same time, we operate actively to do research and enhancement for High quality Customized Inert Alumina Ceramic Packing Catalyst Support Media Porcelain Ball, You would not have any communication problem with us. We sincerely welcome customers all over the world to contact us for enterprise cooperation.

We continue to keep increasing and perfecting our solutions and service. At the same time, we operate actively to do research and enhancement for China Catalyst Support Ball and Supporting Ceramic Balls, With the development and enlargement of mass clients abroad, now we’ve set up cooperative relationships with many major brands. We’ve our own factory and also have many reliable and well-cooperated factories in the field. Adhering to the “quality first, customer first, We are provideing high-quality, low-cost items and first-class service to customers. We sincerely hope to establish business relationship with customers from all over the world on the basis of quality, mutually benefit. We welcome OEM projects and designs.

| Al2O3 | Fe2O3 | MgO | SiO2 | Na2O |

| >99% | <0.1% | <0.5% | <0.2% | <0.05% |

|

Item |

Value |

|

Water absorption (%) |

<1 |

|

Bulk density (g/cm3) |

1.9-2.2 |

|

Specific gravity (g/cm3) |

>3.6 |

|

Operation temp.(max) (℃) |

1650 |

|

Apparent porosity (%) |

<1 |

|

Moh’s hardness (scale) |

>9 |

|

Acid resistance (%) |

>99.6 |

|

Alkali resistance (%) |

>85 |

|

Item |

Value |

|

Water absorption (%) |

<1 |

|

Packing density (g/cm3) |

1.9-2.2 |

|

Specific gravity (g/cm3) |

>3.6 |

|

Operation temp.(max) (℃) |

1650 |

|

Apparent porosity (%) |

<1 |

We continue to keep increasing and perfecting our solutions and service. At the same time, we operate actively to do research and enhancement for High quality Customized Inert Alumina Ceramic Packing Catalyst Support Media Porcelain Ball, You would not have any communication problem with us. We sincerely welcome customers all over the world to contact us for enterprise cooperation.

High quality China Catalyst Support Ball and Supporting Ceramic Balls, With the development and enlargement of mass clients abroad, now we’ve set up cooperative relationships with many major brands. We’ve our own factory and also have many reliable and well-cooperated factories in the field. Adhering to the “quality first, customer first, We are provideing high-quality, low-cost items and first-class service to customers. We sincerely hope to establish business relationship with customers from all over the world on the basis of quality, mutually benefit. We welcome OEM projects and designs.