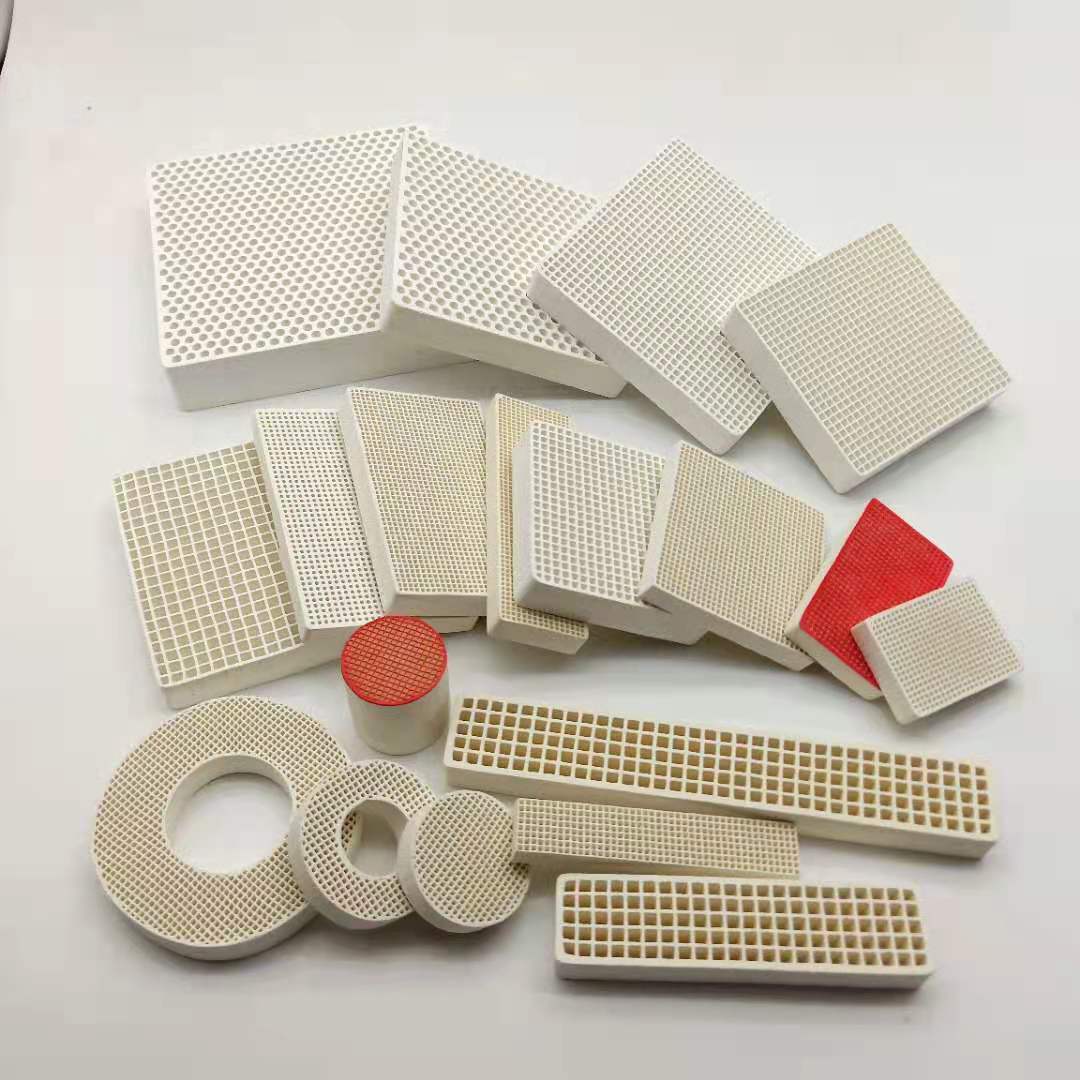

Honeycomb Ceramic Plate for casting and gas filter

Honeycomb Ceramic Plate for casting and gas filter

Honeycomb ceramic filter apply to metal liquid filtration, it is made by material of mullite or cordierite ceramics. With unique high-density straight-pore honeycomb structure, excellent thermal shock resistance, high strength, high porosity and specific surface area. Thereby to improve its adsorption and capturing tiny impurities ability, as to get rid of non-metal impurity and gas, purify metal liquid, make the metal liquid steady and reduce the vortex. It not only reduces the defective index of the casting, prolong the working life of the casting and reduce the casting cost, but also improve mechanic capability and appearance quality of the casting.

Ceramic honeycomb filter is extensively applied to the metallurgic plants of casting and foundry, such as steel, iron, copper and aluminum, etc. It has high mechanical intensity and heat-resistance, removing the metal impurity, refractory scrap, solid refractory alloy and sinter in the molten metal liquid.

Technology: Extruded.

Pore density: 100PCSI, 200PCSI, 300PCSI, etc.

Cell shape: Square, round, hexagon, triangle.

Available range of size: 25 mm to 200 mm.

Available range of thickness: 12 mm to 22mm or as per client’s requirements.

Appearance shape: Round, square and rectangle

Material: Cordierite, mullite, corundum mullite, zircon mullite, zirconia-corundum, high aluminum, silicon carbide and etc.

Maximum working temperature: 1350°C, 1500°C, 1600°C, 1650°C.

Application: Grey iron, ductile iron and malleable iron, aluminum, aluminum alloy, copper, stainless steel and so on.

1. Excellent thermal shock resistance.

2. Unique cellular designs make metal liquid reducing the vortex and reducing the bubbles in the casting.

3. Accurate extrusion die make product quality extremely stable and consistency.

4. Obvious filter effect.

5. Improving the casting surface performance and improving the density of the casting.

6. Improving metal structure and quality prolong the working life of the casting.

7. Good chemical stability, not affected by of melted metal, no change in its chemical compound.

8. Precise dimension and can be used in production line automatic filter mounting equipment.

|

Material |

Cordierite |

|

Volume |

0.45-0.65g/cm3 |

|

Hole density |

200-300 holes/in2 |

|

Hole center distance |

1.12/1.25/1.42mm |

|

hole center distance |

1.8/2.2/2.7mm |

|

Hole fraction |

33.5-46.5% |

|

water absorption rate |

>46% |

|

Softening temperature |

2.0-2.3X10-6 |

|

Carbon monoxide release rate |

≤80ppm |

|

Nitrogen oxide release rate |

≤10ppm |