-

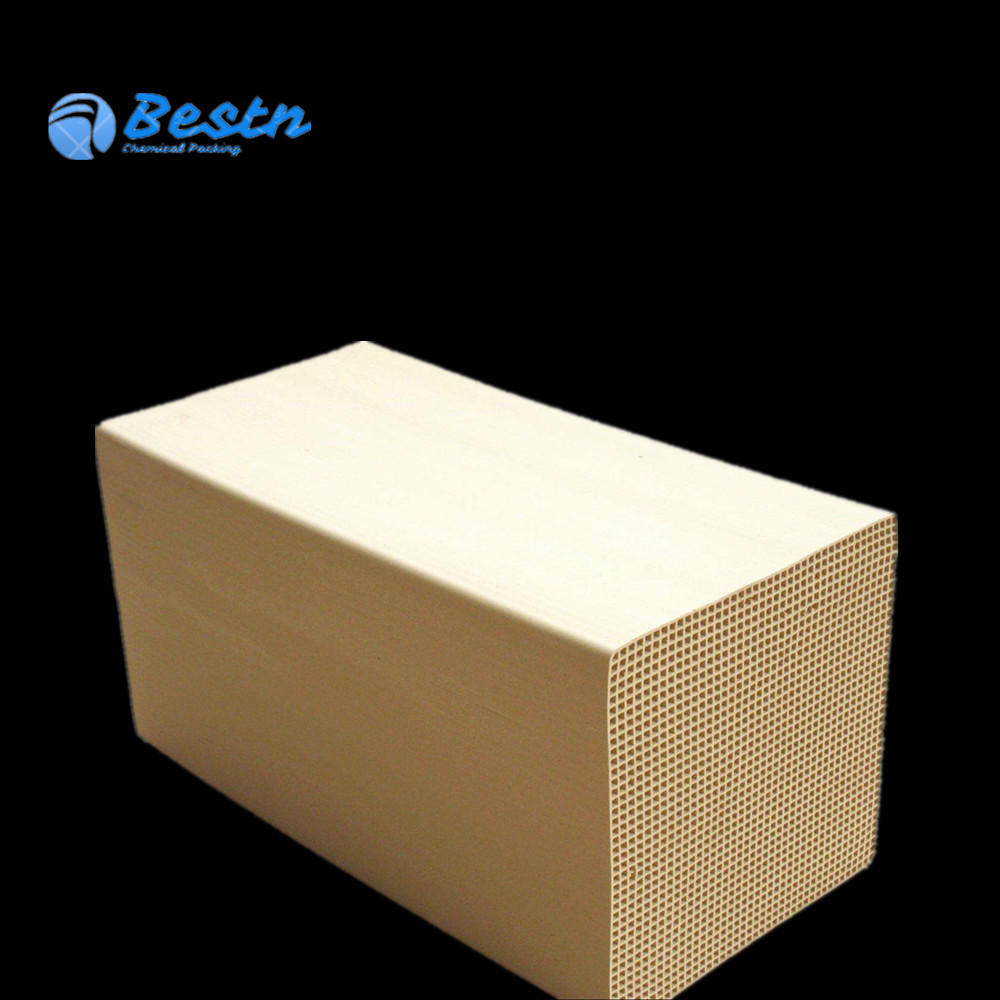

Square shape cordierite honeycomb ceramic accumulator

Regenerative Thermal/Catalytic Oxidizer (RTO/RCO) is used to destroy Hazardous Air Pollutants(HAPs),Volatile Organic Compounds (VOCs) and Ordours emissions etc. Which is extensively applied in the fields of Automotive paint, Chemical industry, Electronic & Electric manufacturing industry, Contact Combustion System and so on. Ceramic Honeycomb is specified as structured regenerative media of RTO/RCO.Size(mm)Numbers of HoleWall thicknesInner wallHole sizeSurface areaPorosity (%)Bulk weight (kg/ m3)150×150×30025×251.21.04.9457468666150×150×30040×400.90.73.0288465725150×150×30043×430.90.72.7693263740150×150×30050×500.80.62.38108263770150×150×30060×600.70.51.99129863784100×100×15026×260.90.73.1087565799100×100×15033×330.80.62.40108363866Product ParametersChemical & Physical IndexCordieriteDense CordieriteCordierite-MulliteMulliteCorundum-MulliteDense AluminaChemical Composition %SiO245-5535-4535-4525-3820-3240-50Al2O330-3840-5040-5050-6565-7345-55MgO10-153-133-130-10-23-5K2O+Na2O<1.0<1.0<1.0<1.0<1.03-6Thermal Expansion Coefficient (10-6/K-1)<2<4<4<5<7≤6.5Specific Heat (J/kg.K)830-900850-950850-1000900-1050900-11001000-1200Working Temperature (°C)<1300<1300<1350<1450<1500<1500Water adsorption(5)≤20≤15≤15≤20≤20≤5We also can make products as your request and actual operating condition. -

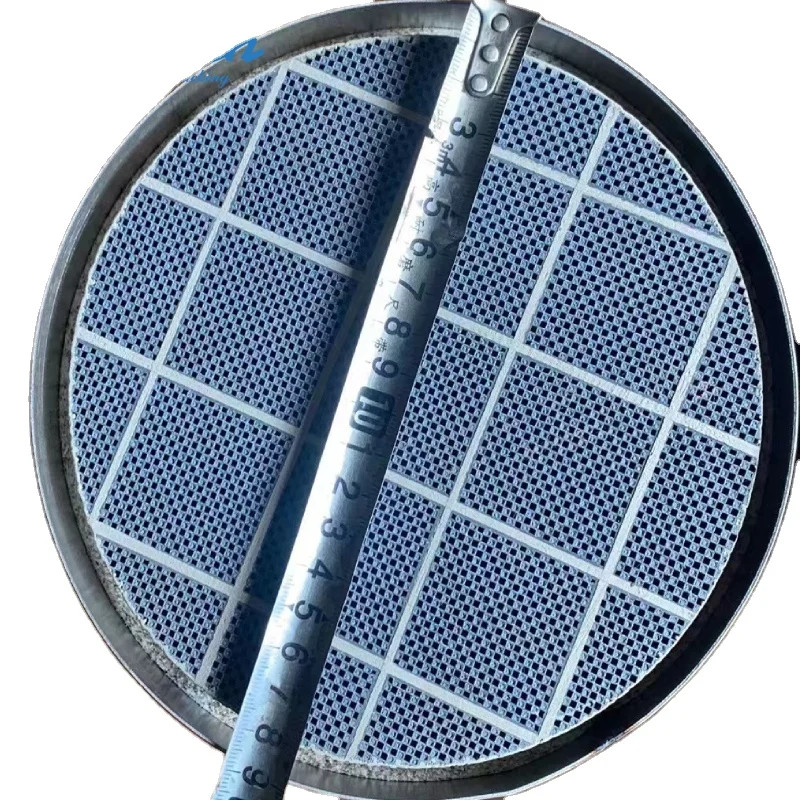

Ceramic Gas Liquid Distributor Groove-Tray Through Liquid Distributor for Rectifying Column

Ceramic liquid distributor has a rough and uneven appearance, with many pore sizes ranging from 6 to 10 millimeters. The product is bowl shaped, with ventilation holes spaced in the middle of the distributor and convection holes spaced around the ventilation holes. An overflow port is set at the upper end of the convection holes, and a flow blocking groove is set on the lower end face of the distributor at the peripheral position of the convection holes. The height of the overflow port shall not exceed one-third of the height of the convection hole.

When the liquid flow rate is high, in order to ensure uniform distribution of gas-liquid convection in the convection hole and

maintain a certain height of liquid, an overflow port is set at the upper end of the convection hole to ensure that uniform

distribution of gas-liquid convection can always be maintained in the packed tower. When the liquid distributor is placed

unevenly, a flow blocking groove is set on the lower end face of the distributor body around the convection hole to prevent liquid from flowing in the bottom surface of the distributor body. -

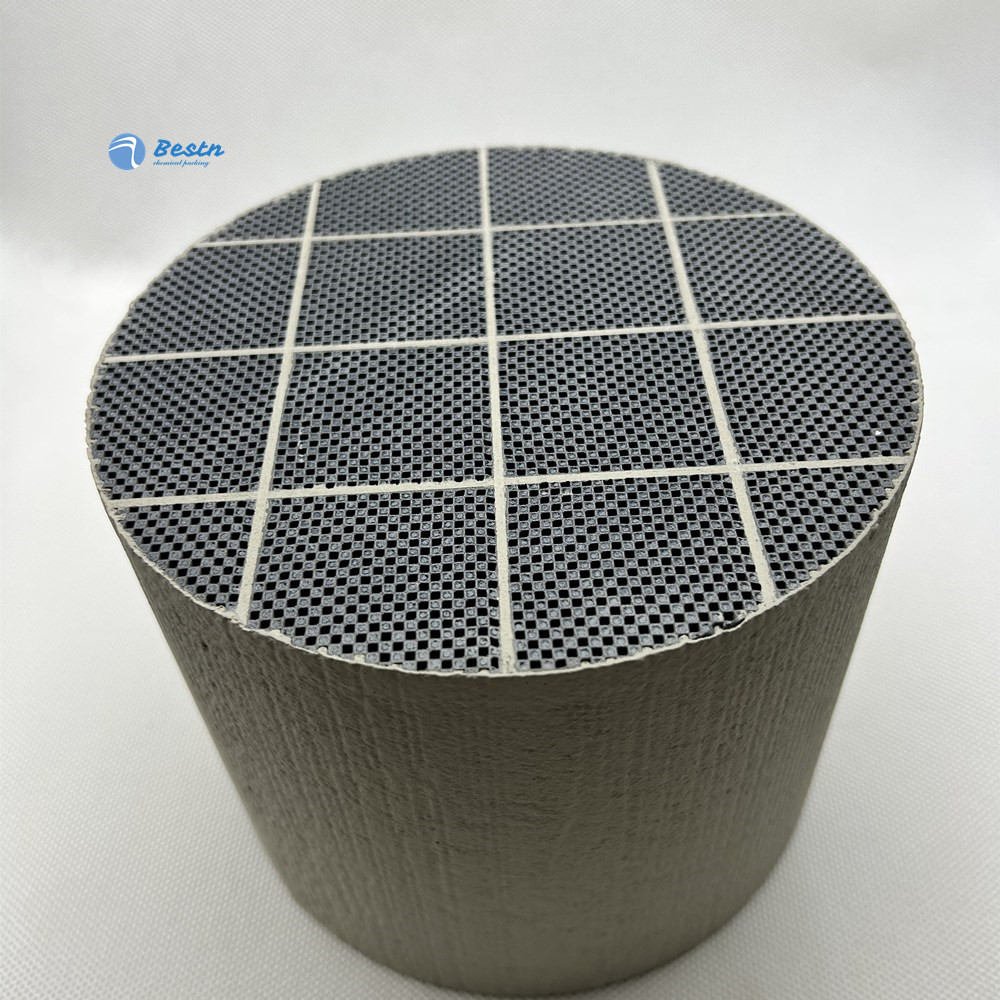

Customize Sic DPF & Silicon Carbide Diesel Particulate Filter for Catalytic Converter

Customize Sic DPF & Silicon Carbide Diesel Particulate Filter for Catalytic Converter

Diesel particulate filter is mainly used in the diesel engine tail gas purifying system to solve the air pollution problem. It

adopts structure of honeycomb, and sets up independent opening and blocking up passages in both ends and the waste gas enters from one open end, then goes through the porous beehive wall, and finally discharges from adjoining passage. The carbon particulates are left over on passage wall because they are too big to pass through wall hole and won’t be discharged to air.Diesel particulate filter can effectively remove black smoke (PM e.g.: Hydrocarbons, soot) from diesel engine exhaust emission,usually DPF removes 90% or more of the soot.Feature & Advantages

1. Low pressure drop.

2. Low coefficient of thermal expansion.

3. Good thermal shock resistance.

4. High temperature resistance, good resistance to chemical corrosion.

5. High porosity, pore size distribution uniform, high filter specific surface area.

6. Long-term durability performance.

7. High particulate trapping efficiency, suitable for all kinds of regeneration.

Diesel particulate filter is suitable for exhaust gas purification of various kinds of diesel vehicles and ships. We can produce

different materials of DPF: cordierite diesel particulate filter and silicon carbide diesel particulate filter.

If you want know more things about the DPF, please contact us directly, I will do my best to service for youPacking:

-

Metallic DPF Coating Honeycomb Catalyst Substrate Metal Carrier Euro 4/5 for Automobile/Vehicle Catalytic Converter

Metal carrier three-way catalyst is the most important external purification device installed in automobile exhaust system. It can convert harmful gases such as carbon monoxide, hydrocarbons and carbon oxides discharged from automobile exhaust into harmless through oxygen compounds and reduction. of carbon dioxide, water and nitrogen.

-

OBD EURO 3/4/5 Car Exhaust Universal Catalytic Converter Three Way Catalyst Converter Catalytic

The three-way catalytic converter is the most important external purification device installed in the automobile exhaust system. The three-way catalytic reactor is similar to a muffler. Its outer surface is made of double-layer stainless steel sheet in a cylindrical shape. A heat-insulating material-asbestos fiber felt is installed in the double-layer sheet sandwich. Inside, there is a purifying agent in the middle of the mesh partition. The purifying agent is composed of a substrate and a catalyst. The main function of the 3 way catalytic converter is to convert harmful gas into harmless gas, which plays a role in protecting the environment. It is installed in the exhaust pipe of a car, close to one end of the engine. After the exhaust gas is discharged, it is converted through three-way catalysis. After the exhaust gas is converted, it is discharged outside the car.

-

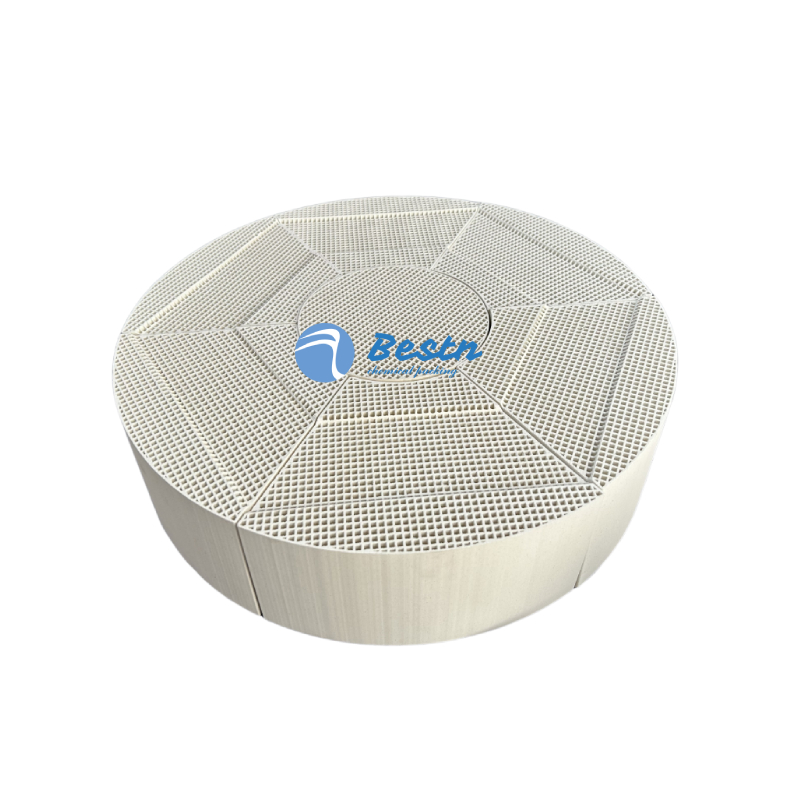

Cordierite Cylindrical Fan-shaped Honeycomb Ceramic Regenerator for Ladle and Intermediate Ladle Baking Device

Honeycomb ceramic regeneration have significant advantages such as high temperature resistance, corrosion resistance, good thermal shock stability, high strength, large heat storage capacity, and good thermal conductivity, greatly increasing their effectiveness and service life.

-

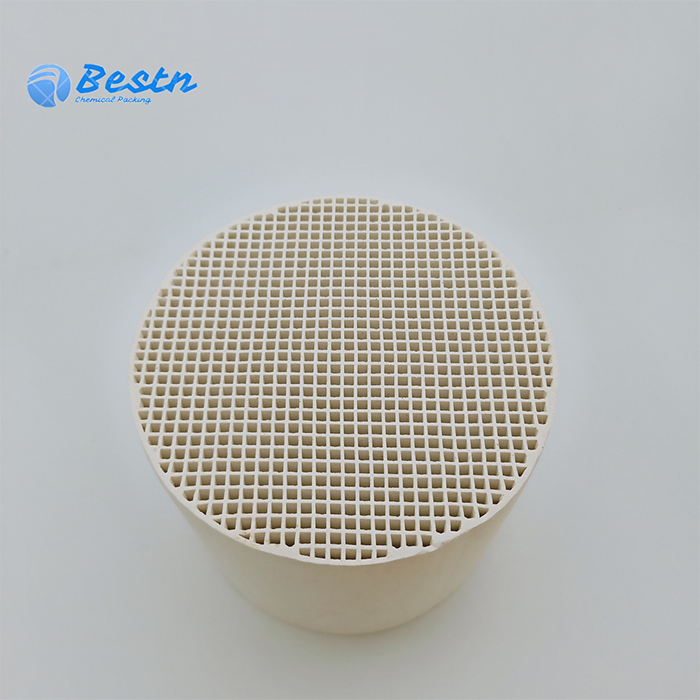

Thermal Storage RTO RCO Ceramic Honeycomb For Heat Recovery

High Temperature Air Combustion (HTAC) is new-type combustion technology with great energy-saving and environment protection. This technology is to make two regenerator to absorb heat and send out heat alternatively through the reversal valve, recuperate the heat of the exhaust gas to the maximum extent, then heat the combustion-supporting air and coal gas to over 1000°C, even the inferior fuel of lower calorific power can also catch fire steadily and burns high-efficiently. The heat storage honeycomb ceramic as heat exchange media is the key part of HTAC.

-

Waterproof Air Filters 100x100x100mm Honeycomb Activated Carbon Cube for Vocs Treatment

Honeycomb activated carbon is made from coal based activated carbon as raw material, pressed by a bee mold, and activated and fired at high temperature. Honeycomb activated carbon has the characteristics of large specific surface area, low through-hole resistance, developed micropores, high adsorption capacity, and long service life, and is widely used in air pollution control. The honeycomb activated carbon adsorption method is used, which means that the pollutants in the exhaust gas are adsorbed when the exhaust gas comes into contact with porous activated carbon with a large surface, thereby playing a purification role.

-

Lacunaris ceramic carrier ring with 7 holes as Catalyst

The ceramic carrier have stable chemical features and a low rate of water absorption, resist high temperatures and high pressure, and also resist the corrosion of acid, alkali and some other organic solvents. They can stand the change in temperature during the manufacturing process.

-

Metal Exhaust Catalyst Universal Ceramic Honeycomb Catalytic Converter for BMW E63 Q7 Audi Car Exhaust System

Metal three-way catalyst is the most important external purification device installed in automobile exhaust system. It can convert harmful gases such as carbon monoxide, hydrocarbons and carbon oxides discharged from automobile exhaust into harmless through oxygen compounds and reduction. of carbon dioxide, water and nitrogen.

-

Coating Standard Euro V Euro VI Sic DPF Diesel Particulate Filter for Truck

Customize Sic DPF & Silicon Carbide Diesel Particulate Filter for Catalytic Converter

Diesel particulate filter is mainly used in the diesel engine tail gas purifying system to solve the air pollution problem. It

adopts structure of honeycomb, and sets up independent opening and blocking up passages in both ends and the waste gas enters from one open end, then goes through the porous beehive wall, and finally discharges from adjoining passage. The carbon particulates are left over on passage wall because they are too big to pass through wall hole and won’t be discharged to air.Diesel particulate filter can effectively remove black smoke (PM e.g.: Hydrocarbons, soot) from diesel engine exhaust emission,usually DPF removes 90% or more of the soot. -

Good Heat Resistance Temperature and Thermal Conductivity Silicon Carbide Diesel Particulate Filter with Metal Shell

Customize Sic DPF & Silicon Carbide Diesel Particulate Filter for Catalytic Converter

Diesel particulate filter is mainly used in the diesel engine tail gas purifying system to solve the air pollution problem. It

adopts structure of honeycomb, and sets up independent opening and blocking up passages in both ends and the waste gas enters from one open end, then goes through the porous beehive wall, and finally discharges from adjoining passage. The carbon particulates are left over on passage wall because they are too big to pass through wall hole and won’t be discharged to air.Diesel particulate filter can effectively remove black smoke (PM e.g.: Hydrocarbons, soot) from diesel engine exhaust emission,usually DPF removes 90% or more of the soot.