-

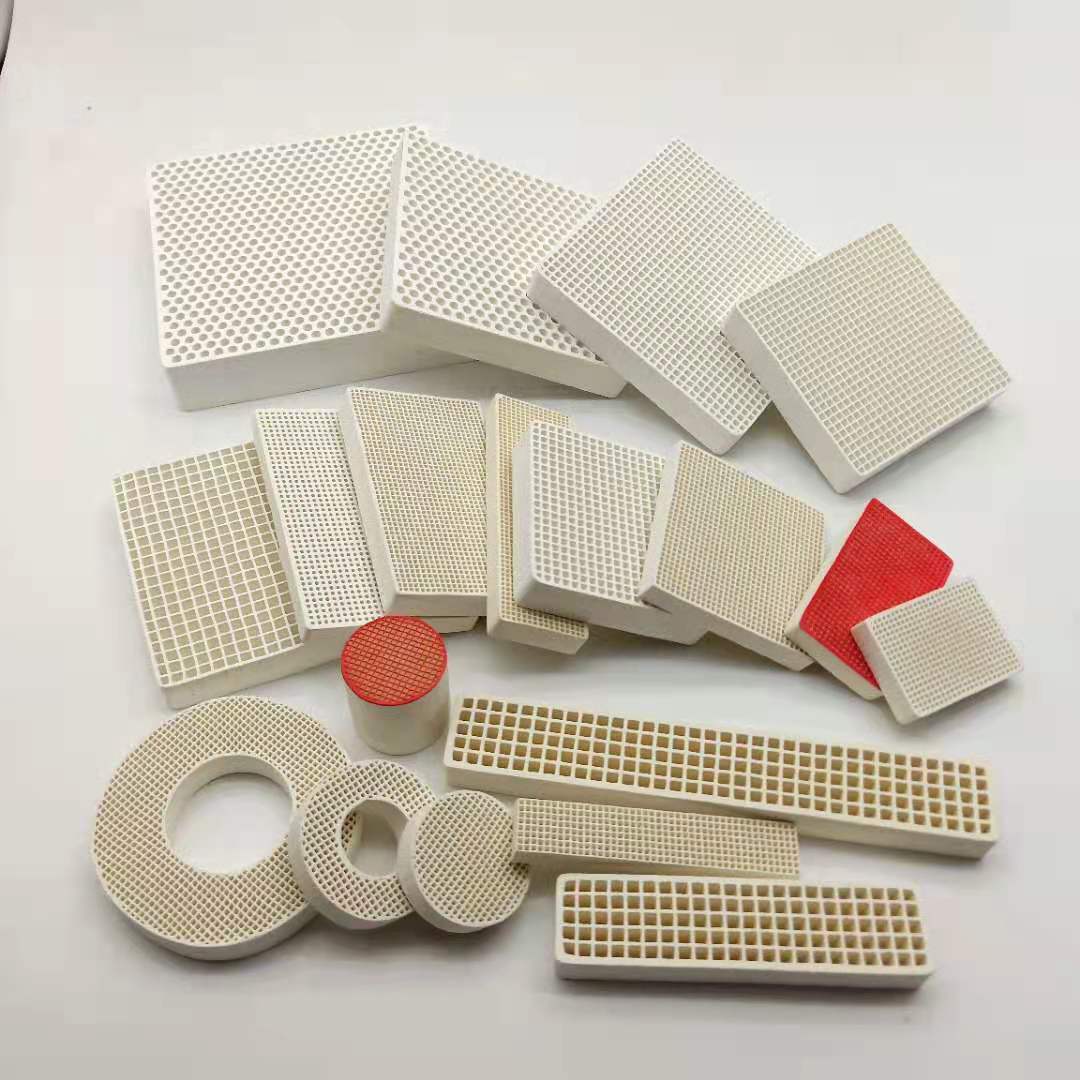

Hexagonal Honeycomb Ceramic Wood Stove Catalytic Converter with Stainless Steel Shell for Fireplace Flue

Wooden stove converter generally use mullite honeycomb ceramics and stainless steel material as the shell. Due to its good heat resistance and high temperature resistance, it can be used for wooden stove and fireplaces. The honeycomb shaped pore size can filter some impurities and can be used for smoke exhaust port filtration. If it is necessary to reduce CO emissions, coatings can be customized according to the application environment – palladium (Pd), platinum (Pt), rhodium (Rh) ratio, it can lock the heat and reduce consumption.

-

Ceramic Honeycomb Catalyst Substrate for Vehicle/Motorcycle

The catalyst carrier is mainly used in the automotives and other high-temperature process exhaust. The main material is cordierite, after coated the catalyst, catalytic conversion of the exhaust, so as to achieve the national emission standards. It has characteristics of large surface area, small expansion coefficient, high strength, high water absorption, and good matching with the catalytic active component, heating up fast and so on.

-

Honeycomb Ceramic Plate for casting and gas filter

Honeycomb ceramic filter apply to metal liquid filtration, it is made by material of mullite or cordierite ceramics. With unique high-density straight-pore honeycomb structure, excellent thermal shock resistance, high strength, high porosity and specific surface area. Thereby to improve its adsorption and capturing tiny impurities ability, as to get rid of non-metal impurity and gas, purify metal liquid, make the metal liquid steady and reduce the vortex. It not only reduces the defective index of the casting, prolong the working life of the casting and reduce the casting cost, but also improve mechanic capability and appearance quality of the casting.

Ceramic honeycomb filter is extensively applied to the metallurgic plants of casting and foundry, such as steel, iron, copper and aluminum, etc. It has high mechanical intensity and heat-resistance, removing the metal impurity, refractory scrap, solid refractory alloy and sinter in the molten metal liquid.

-

Infrared Honeycomb Ceramic Plate for burning

Infrared Honeycomb Ceramic Plate, It’s widely used in gas radiant heaters and plays the most important part in those applications. The interlaced corrugated surface of the ceramic tile combined with honeycomb design basis provides a superb surface area and working burning surface. We have also adopted the best raw material and new formula to maximize the micro-porosity of the tile. With all these advantages, the oxygen mix completely with the gas, burning without flame, emitting high efficiency far infrared ray and radiant heat, saving up to 40%-50% energy cost .