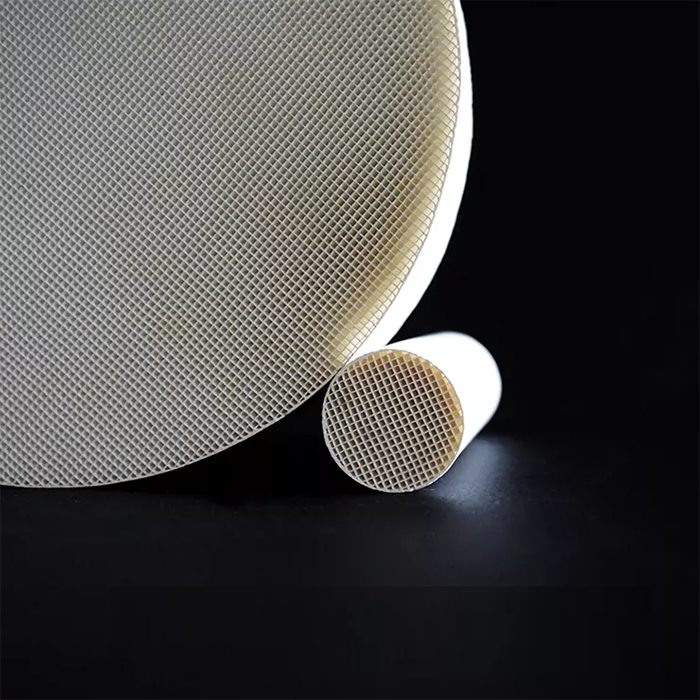

Manufacturer for Honeycomb Ceramic Plate - Ceramic Honeycomb Catalyst Substrate for Vehicle/Motorcycle – Bestn

Manufacturer for Honeycomb Ceramic Plate - Ceramic Honeycomb Catalyst Substrate for Vehicle/Motorcycle – Bestn

Manufacturer for Honeycomb Ceramic Plate - Ceramic Honeycomb Catalyst Substrate for Vehicle/Motorcycle – Bestn Detail:

● Large specific surface area: to ensure full access to the exhaust gas with the catalyst.

● Stable water absorption: to ensure the catalyst evenly firmly attached to the surface of the catalyst carrier.

● Warm-up: after start-up the engine, the temperature of the carrier can reach the catalyst activation temperature in the shortest possible time.

● Low exhaust resistance: the engine’s exhaust resistance is small, to ensure that doesn’t affect the engine performance.

● High strength: the operating environment of the catalyst carrier is in the bumpy car, so the catalyst carrier must be high strength without being external damage.

● Good assembly: the carrier is an exhaust assembly parts, only good appearance and precise dimensions can ensure perfect assembly.

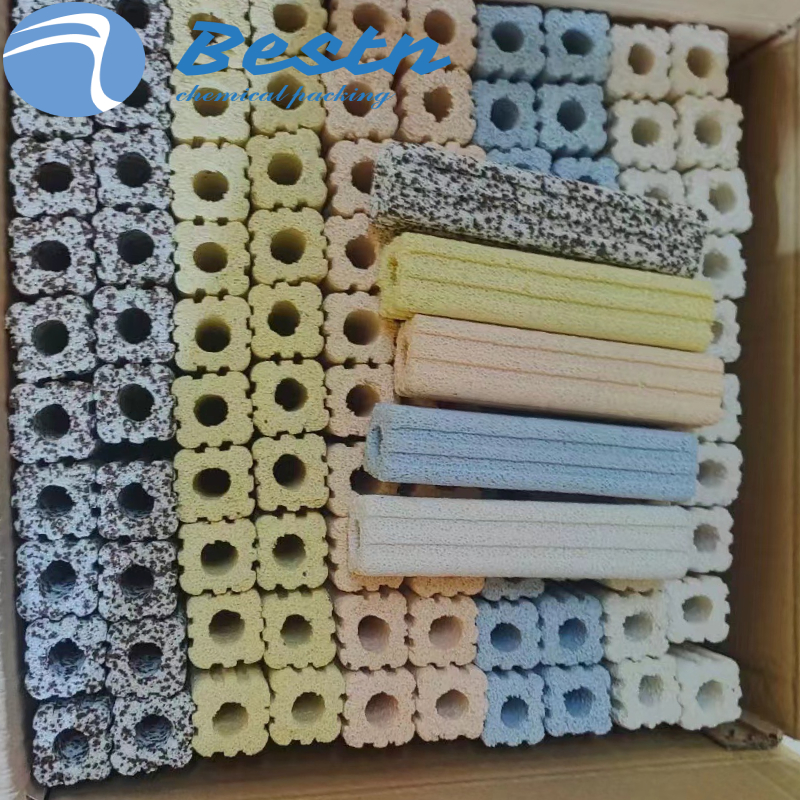

Product detail pictures:

Related Product Guide:

We have quite a few great team customers very good at internet marketing, QC, and dealing with kinds of troublesome trouble while in the output approach for Manufacturer for Honeycomb Ceramic Plate - Ceramic Honeycomb Catalyst Substrate for Vehicle/Motorcycle – Bestn , The product will supply to all over the world, such as: Lesotho, Mombasa, Zurich, We have top engineers in these industries and an efficient team in the research. What is more, we have our own archives mouths and markets in China at low cost. Therefore, we can meet different inquiries from different clients. Please find our website to check more information from our products.

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.