-

Virgin HDPE Material Mbbr Filter Media Biochip for Water Treatment Plant

Bio Chips are made of high-quality polyethylene, which are with long life time of 20years, excellent self cleaning ability and excellent protected active surface area of >5,500 m²/m³, the removal rates up to 10 times higher than conventional media carriers.

Bio Chips not only be used for the immobilization of microorganisms which are in charge of the different biological water treatment processes,but also be used as packing media for water coolers, oil water separators, and de-nitrification systems for polluted fish farms…etc.highly improve the biological treatments’ efficiency -

Customize Sic DPF & Silicon Carbide Diesel Particulate Filter for Catalytic Converter

Customize Sic DPF & Silicon Carbide Diesel Particulate Filter for Catalytic Converter

Diesel particulate filter is mainly used in the diesel engine tail gas purifying system to solve the air pollution problem. It

adopts structure of honeycomb, and sets up independent opening and blocking up passages in both ends and the waste gas enters from one open end, then goes through the porous beehive wall, and finally discharges from adjoining passage. The carbon particulates are left over on passage wall because they are too big to pass through wall hole and won’t be discharged to air.Diesel particulate filter can effectively remove black smoke (PM e.g.: Hydrocarbons, soot) from diesel engine exhaust emission,usually DPF removes 90% or more of the soot.Feature & Advantages

1. Low pressure drop.

2. Low coefficient of thermal expansion.

3. Good thermal shock resistance.

4. High temperature resistance, good resistance to chemical corrosion.

5. High porosity, pore size distribution uniform, high filter specific surface area.

6. Long-term durability performance.

7. High particulate trapping efficiency, suitable for all kinds of regeneration.

Diesel particulate filter is suitable for exhaust gas purification of various kinds of diesel vehicles and ships. We can produce

different materials of DPF: cordierite diesel particulate filter and silicon carbide diesel particulate filter.

If you want know more things about the DPF, please contact us directly, I will do my best to service for youPacking:

-

Metallic DPF Coating Honeycomb Catalyst Substrate Metal Carrier Euro 4/5 for Automobile/Vehicle Catalytic Converter

Metal carrier three-way catalyst is the most important external purification device installed in automobile exhaust system. It can convert harmful gases such as carbon monoxide, hydrocarbons and carbon oxides discharged from automobile exhaust into harmless through oxygen compounds and reduction. of carbon dioxide, water and nitrogen.

-

Aquarium Foam Filter Media Bacteria House Cube Multi Colour Culture Brick for Koi Pond Filtration

Bacterial brick is a biological filter material for culturing nitrifying bacteria.

-

W Shape PP FRPP Vane Demister with Hook

Vane type demister/mist eliminator also known as baffled type mist eliminator/demister is a high capacity inertial separator. Vane mist eliminators consist of closely spaced corrugated plates, which cause the mist-laden gas to change direction several times from inlet to outlet, that force entrained liquid droplets to impinge on the vane surfaces where they form a liquid film and drain. Useable in either vertical (upward) or horizontal flow designs.

-

OBD EURO 3/4/5 Car Exhaust Universal Catalytic Converter Three Way Catalyst Converter Catalytic

The three-way catalytic converter is the most important external purification device installed in the automobile exhaust system. The three-way catalytic reactor is similar to a muffler. Its outer surface is made of double-layer stainless steel sheet in a cylindrical shape. A heat-insulating material-asbestos fiber felt is installed in the double-layer sheet sandwich. Inside, there is a purifying agent in the middle of the mesh partition. The purifying agent is composed of a substrate and a catalyst. The main function of the 3 way catalytic converter is to convert harmful gas into harmless gas, which plays a role in protecting the environment. It is installed in the exhaust pipe of a car, close to one end of the engine. After the exhaust gas is discharged, it is converted through three-way catalysis. After the exhaust gas is converted, it is discharged outside the car.

-

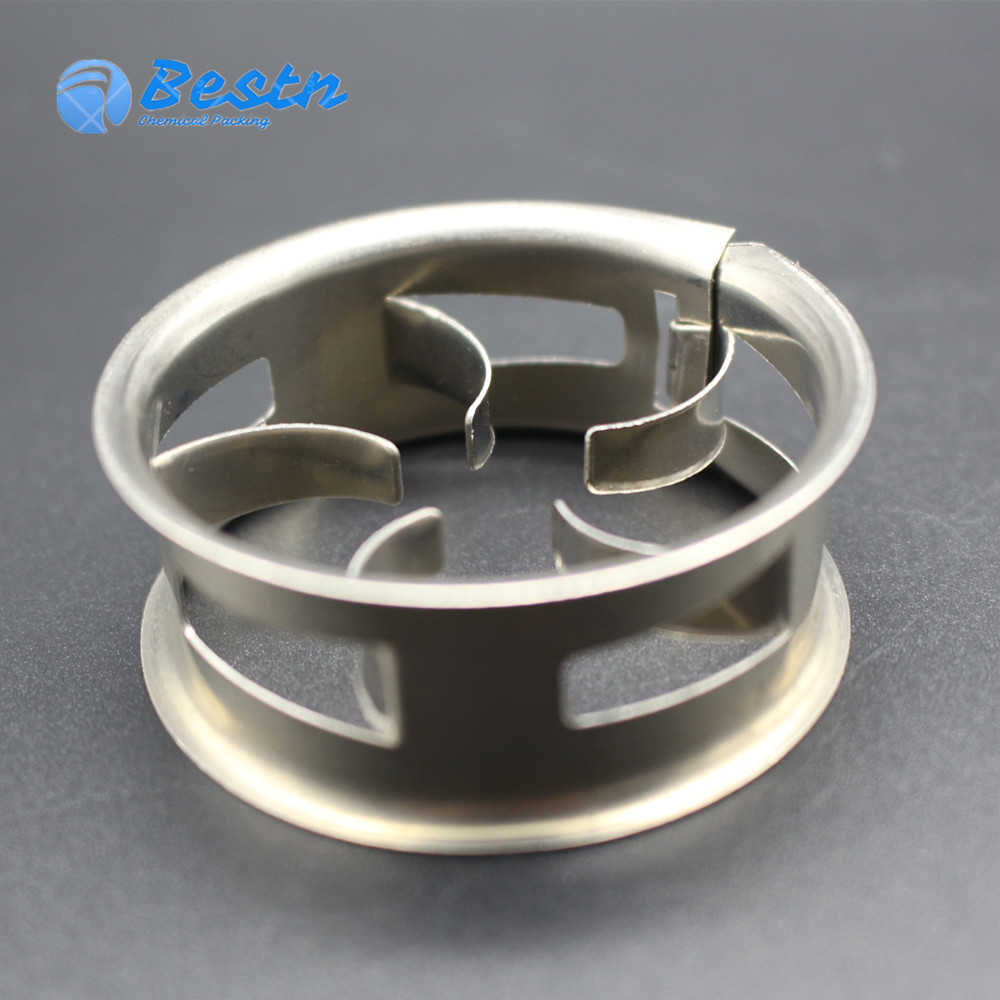

SS304 304L 316L 316L Metal Cascade Mini Ring, Hooked CMR

Cascade mini ring is made of materials like carbon steel, stainless steel or Aluminum alloy, etc. The product has features such as thin wall, heat resistant, high free volume, high capacity, low resistance, high separation efficiency and so on. It is especially suitable for rectification towers under vacuum to treat thermosensitive, decomposable, polymerizable or cokable systems, so it is widely used in packing towers in petrochemical industry, chemical fertilizer industry and environmental protection, etc.

-

Plastic PP Mist Eliminator Demister Mesh for Gas Liquid Separation

Demister pad, also called mist pad, wire mesh demister, mesh mist eliminator, catching mist, mist eliminator. Demister Pads are woven with multi layer knitted mesh in different densities. It is used in gas entrained mist separation column to guarantee the filtering efficiency

-

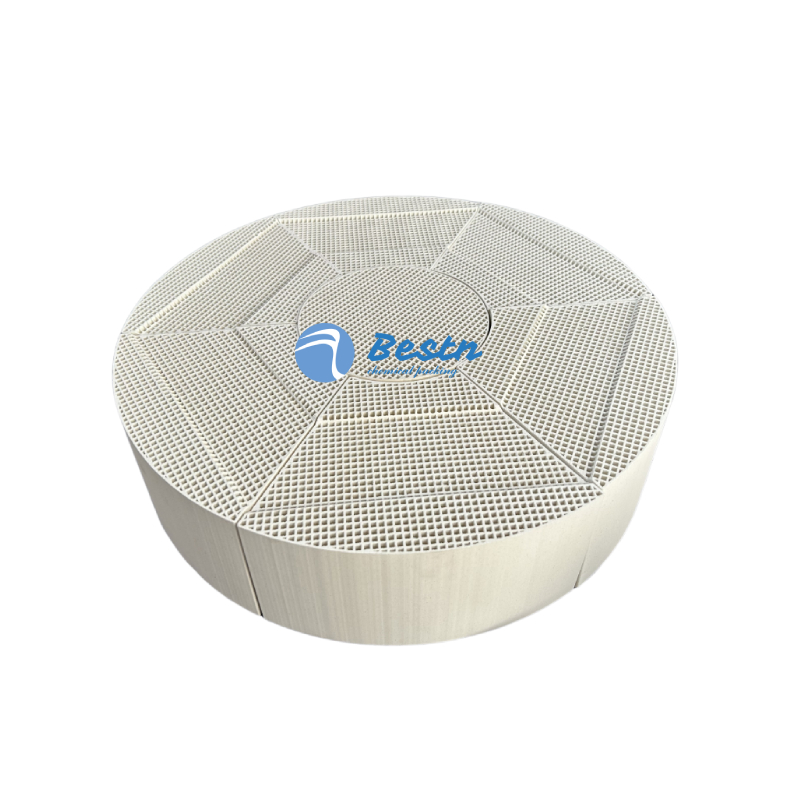

Cordierite Cylindrical Fan-shaped Honeycomb Ceramic Regenerator for Ladle and Intermediate Ladle Baking Device

Honeycomb ceramic regeneration have significant advantages such as high temperature resistance, corrosion resistance, good thermal shock stability, high strength, large heat storage capacity, and good thermal conductivity, greatly increasing their effectiveness and service life.

-

Heat Storage & Thermal Storage Alumina Ceramic Balls for Industrial Furnaces

Heat storage ceramic ball is made of industrial alumina and refractory kaolin as the main raw materials. It is scientifically formulated, shaped and calcined at high temperature.

-

Fish Tank Aquarium Water Filter Media Hexagonal Bio Glass Ceramic Ring for Water Treatment

The filter quartz ceramic ring is made of natural silicate raw materials and sintered at high temperature, with stable chemical properties.

-

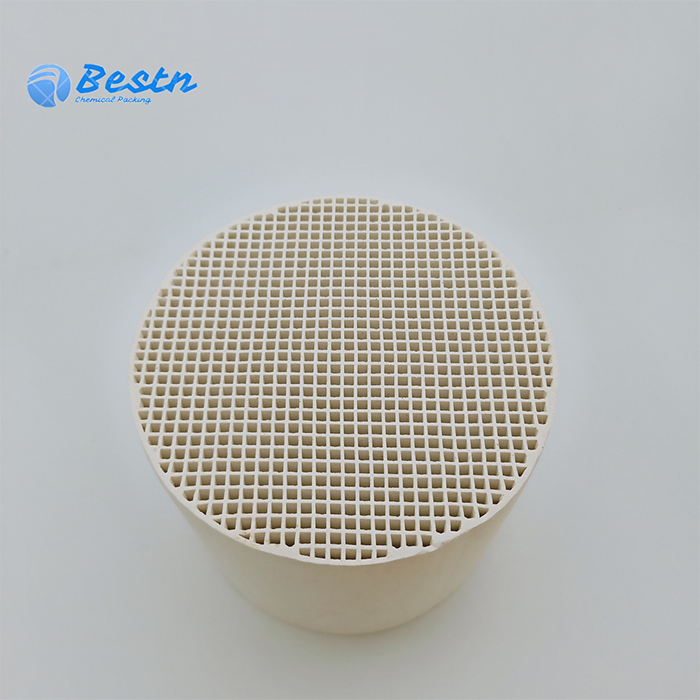

Thermal Storage RTO RCO Ceramic Honeycomb For Heat Recovery

High Temperature Air Combustion (HTAC) is new-type combustion technology with great energy-saving and environment protection. This technology is to make two regenerator to absorb heat and send out heat alternatively through the reversal valve, recuperate the heat of the exhaust gas to the maximum extent, then heat the combustion-supporting air and coal gas to over 1000°C, even the inferior fuel of lower calorific power can also catch fire steadily and burns high-efficiently. The heat storage honeycomb ceramic as heat exchange media is the key part of HTAC.