Single/Double Layer Acid Resistant Ceramic Ball Arch Packing Support Structure for Sulfuric Acid Tower

Single/Double Layer Acid Resistant Ceramic Ball Arch Packing Support Structure for Sulfuric Acid Tower

Ceramic ball arches are also known as ceramic ball arches or acid resistant ceramic ball arches, mainly because they are finely processed using acid resistant chemical ceramic formulas. Selected natural raw materials are carefully designed through a series of process operations such as formula design, ball milling, mud refining, mold design, and so on. The spherical arch produced has a neat and beautiful appearance, and the specifications and dimensions meet the installation requirements of the tower body.

|

Project

|

Unit

|

Index

|

Standard

|

|

Proportion

|

g/cm3

|

2.3-2.6

|

ZBG94003-86

|

|

Water absorption rate

|

%

|

<0.2

|

GB8488-87

|

|

Bending strength

|

Mpa

|

≥45

|

GB8488-87

|

|

Compressive strength

|

Mpa

|

≥200

|

ZBG94003-86

|

|

Thermal stability

|

350-20°C

|

Three times without cracking

|

GB8488-87

|

|

Comprehensive opening rate

|

%

|

≥65

|

|

|

Specifications

|

m

|

≤8.3

|

|

|

Acid resistance

|

%

|

>98.8

|

DIN

|

|

Alkali resistance

|

%

|

>87

|

DIN

|

|

Bending error

|

%

|

<0.5

|

DIN

|

|

Chemical composition

|

SiO2

|

Al2O3

|

K2O

|

Na2O

|

MgO

|

Fe2O

|

Acid resistance

|

|

Index

|

69.8

|

22.5

|

0.95

|

0.82

|

0.12

|

0.49

|

99.8%

|

1. The gas distribution is uniform.

2. High mechanical strength.

3. High safety factor.

4. Good stability.

5. Strong corrosion resistance.

6. And the construction is convenient.

7. Long service life.

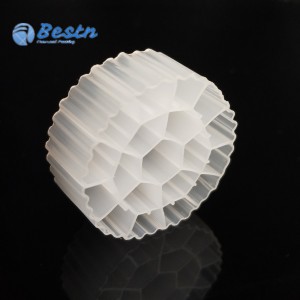

1.Arch brick The main structural part of a spherical arch is a ceramic tile in the shape of an 'I-shaped' shape, so it is also commonly known as an 'I-shaped brick'.

2.Arch foot brick The lower component of a spherical arch is a ceramic tile with a triangular or trapezoidal shape at the bottom.

3.Arch core The middle component of the spherical arch is a conical structure with a cross shaped shape inside.

☟

Ceramic ball arches are ideal materials and efficient tower fillers for corrosion prevention in industrial facilities such as coking and sulfuric acid production (such as smelting tail gas to produce acid, pyrite to produce acid, and sulfur to produce acid), as well as in fertilizer, smelting, light industry, petrochemical, and other industries.