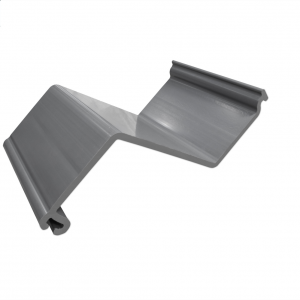

Su622 Su525 Su457 Sz457 Su718 Sz402 PVC Sheet Pile for Water Control Solution

Su622 Su525 Su457 Sz457 Su718 Sz402 PVC Sheet Pile for Water Control Solution

PVC sheet piles are made of rigid polyvinyl chloride with added processing-enhancing, impact-modifying materials, heat and UV stabilizers, and mineral fillers. The sheet piles are manufactured by extrusion as a monolithic profile or co-extruded with a core made of material obtained by recycling architectural PCV, covered with a layer of primary plastic material

|

Product Name

|

PVC sheet pile Plastic sheet pile

|

|

Material

|

PVC

|

|

Width

|

457 mm or Customization

|

|

Section depth

|

254 mm or Customization

|

|

Length

|

Customization

|

|

Thickness

|

11.18mm or Customization

|

|

Color

|

Grey/customization

|

|

Weight

|

11.5±1 kg/m

|

|

Moment of inertia

|

20438 cm4/m

|

|

Section modulus

|

1546cm3/m

|

|

Ultimate moment

|

7153 kg-m/m

|

|

Tensile Strength

|

40.35 Mpa

|

|

Flexural Strength

|

70.5 Mpa

|

|

Modulus of Elasticity

|

2358 Mpa

|

|

Notched Izod impact

|

2.22 Kg/cm

|

|

Heat Deflection Temperature

|

63ºC

|

1. Portable and simple, it can be installed quickly with standard tools and mechanical equipment

2. Low cost - compared with the traditional steel sheet pile construction cost, it can save more than 30%

3. Minimized maintenance work - the complete bearing of plastic sheet piles is as follows: ·

The marine environment : Cracks · Biocorrosion ·Wear,· Rust · Scratch

4. Extreme persistence, durability and special mechanical parameters

5. Ecology - The raw materials of plastic sheet piles can be obtained from the PVC recycling process and can be recycled

6. The locking link is located on the side, away from the maximum load area

7. Clean and beautiful appearance

8. The uniquely designed vinyl plank pile plane is easier to install than other such solutions

9. Simple curvature formation due to special design (together with natural embankment linen)

1.River weir pond agricultural river sewage treatment

2.Embankment management and flood control

3.Rivers, ocean revetments

4.Landscape revetment

5.Soil landslide protection

6.Embankment construction