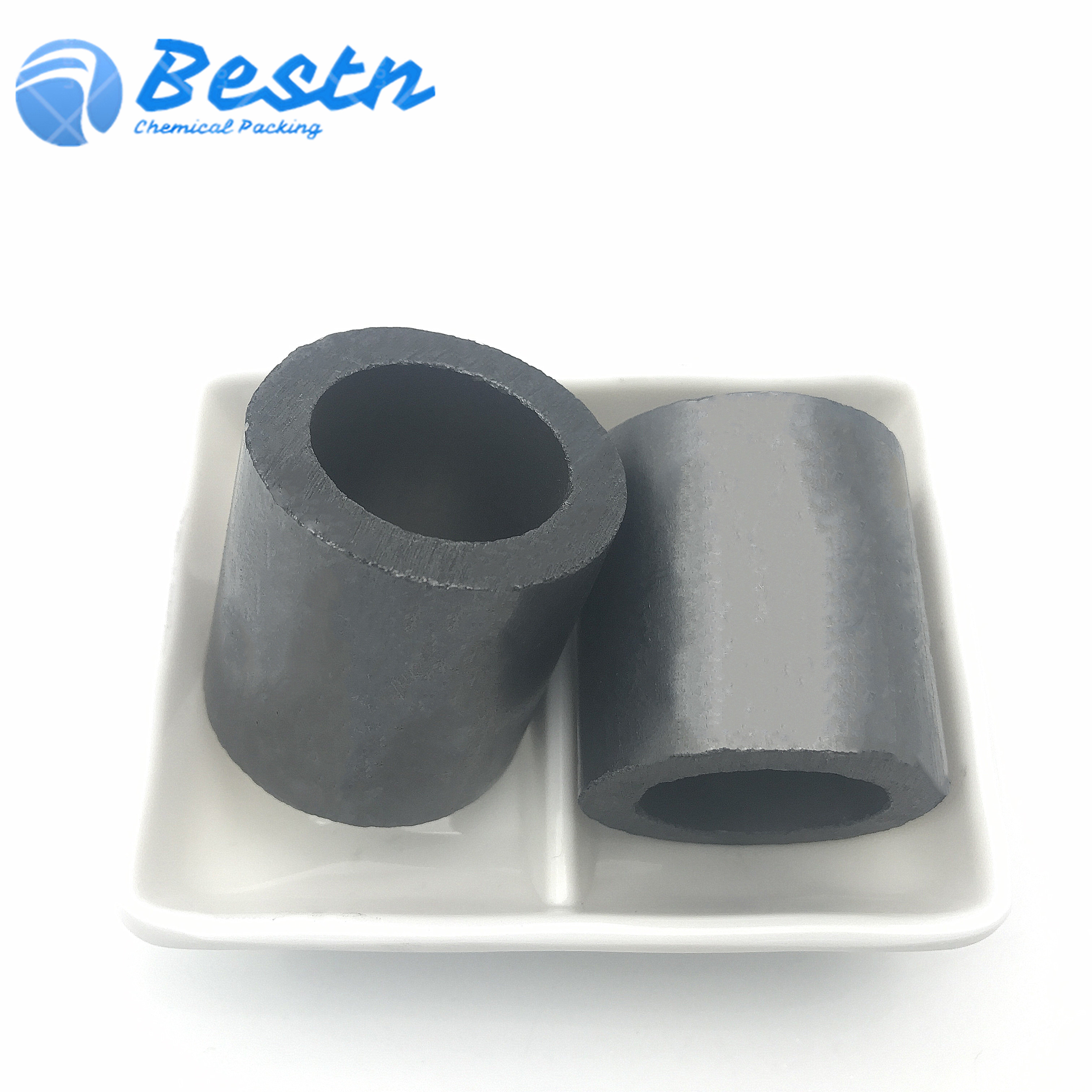

Tower Packing Graphite Carbon Raschig Ring for Petrochemical Industry

Tower Packing Graphite Carbon Raschig Ring for Petrochemical Industry

|

Specification

|

D*H*T

|

Surface area

|

Void Space

|

Bulk Density

|

Bulk Numbers

|

Packing factor

|

|

mm

|

m2/m3

|

m3/m3

|

kg/m3

|

pcs/m3

|

m-1

|

|

|

BSGRR-13

|

13*13*2

|

329

|

0.684

|

600-650

|

320000

|

1028

|

|

BSGRR-19

|

19*19*3

|

220

|

0.54

|

600-650

|

110500

|

914

|

|

BSGRR-25

|

25*25*4

|

194

|

0.73

|

600-650

|

46150

|

565

|

|

BSGRR-38

|

38*38*6

|

125

|

0.68

|

600-650

|

14000

|

406

|

|

BSGRR-50

|

50*50*7

|

120

|

0.78

|

500-550

|

6000

|

252

|

|

BSGRR-80

|

80*80*9

|

76

|

0.68

|

650-700

|

1400

|

243

|

|

The above figures are for raschig rings of general specifications only.

|

||||||

|

Customization as per customers' size requirements is also available.

|

||||||

|

Physical performance index

|

|||

|

Item

|

Value

|

||

|

Bulk Density, Kg/m3

|

≥1500

|

||

|

Compressive strength, Mpa

|

≥79.5

|

||

|

Bending strength, Mpa

|

≥35

|

||

|

Thermal conductivity, W/m.k

|

31.4-40.7

|

||

|

Linear expansion coefficient,1/ºC

|

24.7*10-16 (129ºC)

|

||

|

Heat-resistant temperature, ºC

|

400

|

||

Graphite Raschig ring packing is mainly used in practical applications such as gas absorption, acid gas desorption, scrubbing tower, regeneration tower, fertilizer production, etc. It can also be used as a packing in propane stripper and acid gas absorber. It is used in the furnaces and towers of petrochemical equipment such as alkylation and reforming, and in the purification, absorption, condensation, distillation, evaporation, filtration and washing of highly corrosive materials.